Temporary Fix for Crankshaft Position Sensor: Is It Safe?

The temporary fix for crankshaft position sensor could be a quick solution but not a permanent one.

A failing crankshaft position sensor will create significant disruptions in the performance of your vehicle: stalling, rough idling, and problems starting the engine. The KPS keeps the proper timing and fuel injection in your engine, and repairs should be done without much delay.

Although replacement is the only permanent solution to a faulty sensor, there are times when a temporary fix may help restore functionality.

Temporary repairs, such as tightening loose connections or cleaning a dirty sensor, may temporarily keep your car running and avoid further complications.

This is particularly helpful in cases when access to professional repair services is not immediately available and helps in keeping your car safe and functional until a proper replacement is done.

Read about: How Much Oil Does A 5.3 Vortec Take

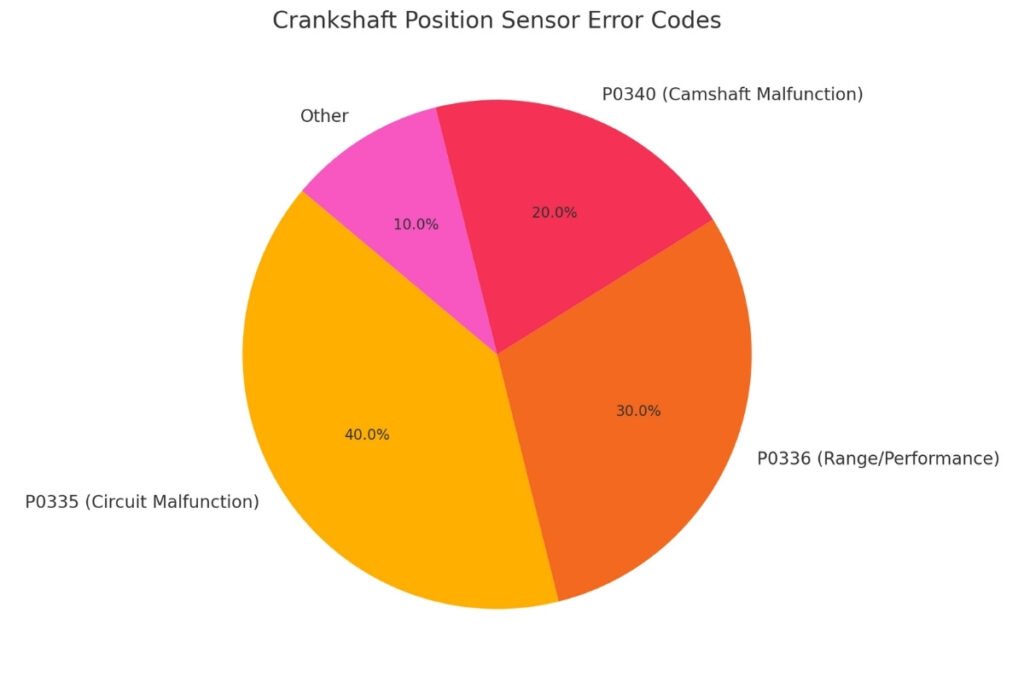

Crankshaft Position Sensor Error Codes

| Error Code | Description | Possible Solution |

| P0335 | Crankshaft Position Sensor Circuit Malfunction | Inspect wiring, clean sensor connections, or replace the sensor. |

| P0336 | Crankshaft Position Sensor Range/Performance Issue | Check for physical damage, ensure proper alignment, or replace. |

| P0340 | Camshaft Position Sensor Circuit Malfunction | Often related to crankshaft sensor; inspect wiring and connections. |

| P0341 | Camshaft Position Sensor Range/Performance | Ensure synchronization between crankshaft and camshaft sensors. |

| P0725 | Engine Speed Input Circuit Malfunction | Related to the crankshaft sensor; inspect the circuit and sensor. |

| P0385 | Crankshaft Position Sensor B Circuit Malfunction | Specific to multi-sensor systems; check Sensor B wiring or replace. |

| P0386 | Crankshaft Position Sensor B Range/Performance | Verify sensor installation, clean connections, or replace Sensor B. |

What is a Crankshaft Position Sensor?

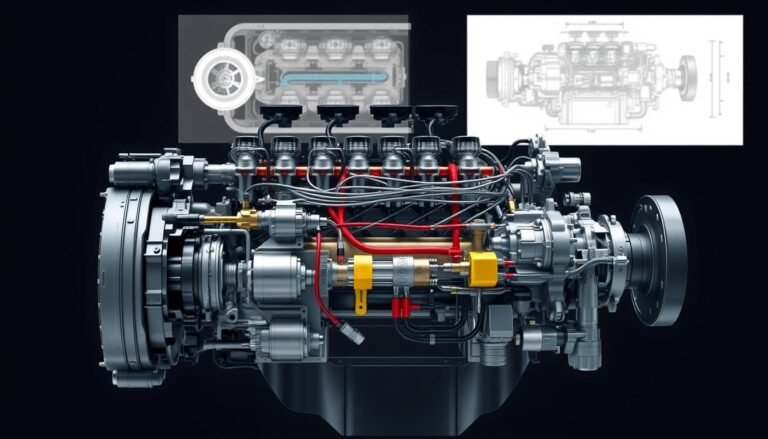

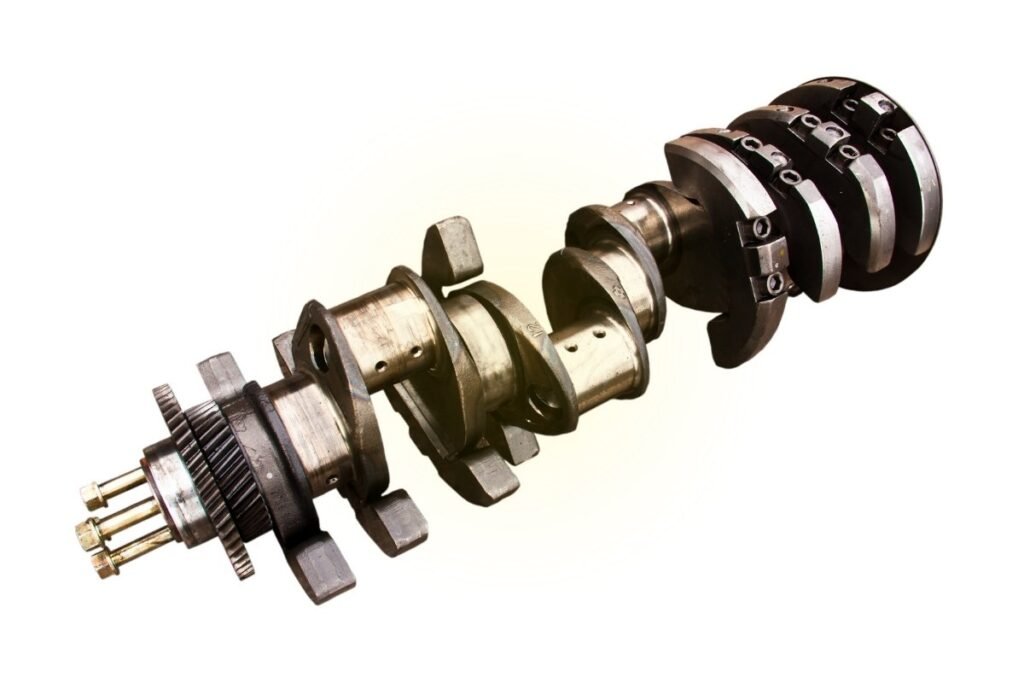

The crankshaft position sensor, or CKP sensor, is one of the most vital parts in modern vehicles, which ultimately monitor the position and rotational speed of the crankshaft.

It plays a vital role in ensuring the smooth running of the engine with efficiency. It transmits data to the engine control unit, which then uses the information to manage key functions of the engine, including ignition timing and fuel injection.

The crankshaft position sensor makes sure that the engine timing is appropriate by synchronizing the crankshaft rotation with other components of the engine. This enables the ECU to fire the spark plugs at the right time and inject fuel precisely when needed, thereby maximizing performance and fuel efficiency.

The common symptoms when a crankshaft position sensor starts to fail include several noticeable ones. The common issues include stalling of the engine, rough idling, difficulty in starting the engine, and poor overall performance.

The faulty sensor may trigger the check engine light. It is always good to have early addressing to avoid further damage to the engine.

Causes of Crankshaft Position Sensor Failure

The crankshaft position sensor is durable and can withstand many extreme conditions, including high temperatures and vibrations present in the engine bay.

But, like any part, it may deteriorate with time because of wear and tear and environmental influences. If the sensor then goes bad, the engine loses much-needed information on timing, which hampers performance and its ability to drive well altogether.

Figuring out the reasons for failure and recognition of warning signs can avert breakdowns and costly repairs.

Here are some of the most common reasons for crankshaft position sensor failure, coupled with the signs indicating urgent attention:

Common Reasons for Failure:

- Heat Damage: Overheat generated from the engine degrades the sensor over time.

- Wiring Issues: Chafing, corrosion, and disconnecting of wires may damage the ability of the sensor to send signals to the ECU.

- Contamination: Oil leaks, dirt, or debris accumulation on the sensor will badly impair its functionality.

- Physical Damage: A failure can be caused by road debris or improper installation.

Signs Indicating Immediate Need for Repair:

- Frequent Stalling: The engine might die unexpectedly, at an idle or low speeds.

- No Start Condition: The engine might turn over but not start. This certainly suggests critical sensor malfunction.

- Erratic Performance: Fluctuations in RPM, misfires, or a sudden drop in fuel economy signals problems with the sensor.

- Illuminated Check Engine Light: The ECU will notice the irregular signals and light up the warning light, usually with some trouble codes like P0335 for Crankshaft Position Sensor Circuit Malfunction.

Proper and quick diagnosis and repair are crucial to prevent further engine damage and ensure safe driving.

Is It Safe to Drive with a Faulty Crankshaft Position Sensor?

Driving with a faulty crankshaft position sensor is potentially risking it, as this sensor is crucial for maintaining the appropriate engine timing and performance of your car.

Sometimes driving is possible, but the repercussions might be anything from minor inconvenience to serious engine damage.

Risks of Continuing to Drive:

- Engine Stalling: Engine stalling is also possible with a faulty sensor; this can be really dangerous, especially when one travels at high speeds or traffic.

- Reduced Performance: There can be sluggish acceleration, misfiring, and rough idling-all these make driving ineffective and unsafe.

- Increased Fuel Consumption: The ECU cannot properly optimize fuel injection without the right information about timing, thus leading to bad fuel economy.

- Permanent Engine Damage: Prolonged use of a faulty sensor may cause strain on other engine components, resulting in more extensive and costly repairs.

- No Start Condition: If the sensor fails completely, the vehicle may not start, leaving you stranded.

Situations Where a Temporary Fix Can Be Used:

- Short-Distance Travel: If you need to drive a short distance to a repair shop or a safer location, a temporary fix may suffice.

- Non-Critical Failures: Non-critical failures are usually with minor issues, such as loose wiring or a buildup of dirt. A quick DIY fix in securing wires or cleaning the sensor may temporarily restore partial functionality.

- Emergency Situations: In emergencies when repair cannot be immediate, a temporary fix helps the vehicle keep running until it is properly serviced.

This is always temporarily relieving, while the permanent solution should be paramount and done the soonest possible to avoid further complications that can be hazardous on the road.

Temporary Fix For Crankshaft Position Sensor: A Step-by-Step Guide

If your crankshaft position sensor goes out and you need a quick fix, a DIY repair might get you back to minimal functionality.

Temporary fixes are not a permanent solution but can alleviate in emergency situations or when immediate professional repair is not possible.

The steps below outline how to deal with some common issues like loose connections or contamination in such a way that you get your vehicle to a repair shop or to a safer location.

Always handle with care, keeping in mind that this should be replaced properly as soon as possible to avoid long-term damage.

Steps to Do the Temp Fix:

Problem Identification Techniques:

Using an OBD-II scanner to read any active trouble code relative to the crankshaft position sensor, such as P0335. Observe symptoms, such as engine stalling, rough idling, or difficulty starting, to confirm that this is the problem.

Look at and Clean the Sensor and Its Connectors:

Find the crankshaft position sensor. Consult your vehicle owner’s manual for its location. Clean the sensor of oil, dirt, or other debris with a lint-free cloth and some electronic cleaner spray.

Temporarily Secure Wiring:

Look for frayed or disconnected wires in the wiring harness. Reconnect all loose wires and secure them with heat-resistant electrical tape.

Stabilize with the Use of Heat-Resistant Electrical Tape or Zip Ties:

If the sensor itself is slightly loose, then the use of zip ties or tape will help in its stabilization. Make sure that the sensor does not touch hot or moving parts.

Reset the ECU if Needed:

Disconnect the negative terminal of the battery for about 10 minutes to reset the engine control unit. Reconnect the battery, and see if it makes the symptoms improve.

Note:

These steps are temporary relief to make the situation better, not a cure for the root problem. A non-permanent solution like this should be replaced with a proper one as soon as possible.

How Long Does a Temporary Fix Last?

Well, everything is depended on lots of factors. By definition, a temporary fix is a little unstable and intended to apply for just short time use.

Here are key points to consider:

Nature of the Issue:

For minor issues, such as a dirty sensor or loose wiring, a temporary fix could last for days to weeks. In cases of severe damage to the sensor or internal failure, the fix might only hold for a few hours or not at all under demanding conditions.

Driving Conditions:

The temporary fix may last longer in cases of mild driving conditions, such as short commutes or highway cruising. On the other hand, rough roads, heavy traffic, or extreme temperatures can quickly render the fix ineffective.

Quality of the Temporary Fix:

The quality of the temporary fix can be improved by using appropriate materials, such as heat-resistant electrical tape, proper cleaning solutions, or secure stabilization methods. Poorly performed fixes may fail almost immediately.

Impact of Engine Stress:

High-stress situations, such as towing, rapid acceleration, or high RPMs, can cause the temporary solution to fail sooner due to increased engine vibrations and heat.

Sensor Location and Accessibility:

Sensors exposed to higher levels of dirt, oil, or heat, especially near exhaust systems, are more likely to cause temporary fixes to fail quickly.

Sensor Accessibility

| Vehicle Model | Sensor Location | Repair Difficulty |

| Sedan A | Front of engine block | Easy |

| SUV B | Behind timing cover | Moderate |

| Truck C | Near crankshaft pulley | Difficult |

Importance of Scheduling a Permanent Repair

Whatever the outcome of the temporary fix, the root cause should be addressed as soon as possible. A bad crankshaft position sensor would affect the timing and ignition of the engine, which in turn would result in:

- Permanent damage to the engine.

- Poor fuel economy.

- Safety compromise on the road.

Make it a point to visit a professional mechanic or replace the sensor yourself in order to keep your car running reliably and safely. Temporary fixes are just that-temporary fixes, not solutions.

5.3 Crankshaft Position Sensor Problems

The 5.3 Crankshaft Position Sensor is an essential part in your vehicle’s engine management system; however, it’s no stranger to encountering issues itself.

This sensor can fail due to wear, damage, or specific environmental conditions, and usually when this component malfunctions, noticeable symptoms appear in your car’s performance.

Here are the common problems a 5.3 Crankshaft Position Sensor may have.

1. Wear and Tear Leading to Sensor Failure

The 5.3 crankshaft position sensor degrades over time because of being continuously exposed to extreme heat and vibrations coming from the engine. This wear can cause the sensor to fail in transmitting correct data across to the ECU.

2. Wiring or Connector Issues

Damaged, corroded, or loose wiring is a common failure of the crankshaft position sensor. Wiring problems interfere with the communication between the sensor and ECU, hence causing misfires or rough engine running.

3. Oil or Debris Contamination

Oil leaks and accumulated dirt coat the sensor, affecting its performance in monitoring the crankshaft position. Contaminants on the sensor may cause erratic performance of the engine or complete failure of the sensor altogether.

4. Intermittent Signal Loss

The 5.3 crankshaft position sensor may have signal disruptions due to internal damage or loose connections. This can result in the engine stalling without warning or failing to start at all.

5. Electromagnetic Interference (EMI)

When positioned close to other parts that generate electromagnetic fields, it interferes with its signal. It can further create some timing problems, misfires, and poor engine performance.

Symptoms of 5.3 Crankshaft Position Sensor Problems

- Engine dies or shuts off without warning.

- Rough idling or poor engine start-up ability.

- Poor fuel economy and slow acceleration.

- The Check Engine Light turns on, with codes like P0335 appearing most of the time.

Early diagnosis and repair of 5.3 crankshaft position sensor problems are essential in maintaining the performance of an engine. Quick fixes can help in emergency situations, but long-term reliability requires a full replacement.

Costs For Temporary Fixes Versus Permanent Repairs

| Expense Type | Temporary Fix | Permanent Repair |

| Tools and materials | $10–$30 | Included in labor |

| Labor (if professional) | $0 (DIY) | $150–$200 |

| Longevity | 1–7 days | 5+ years |

FAQs

Can I drive with a faulty crankshaft position sensor?

Driving with a faulty crankshaft position sensor is never recommended since it may further cause the engine to stall, rough idling, and performance issues. If you must drive, use a temporary fix only for short distances and prioritize permanent repair.

How much does a crankshaft position sensor replacement cost?

Replacing a crankshaft position sensor will cost between $150 and $300, parts and labor included. It might go as low as $50 to $150 if it’s replaced yourself, depending on your make and model of car.

What are some signs that my crankshaft position sensor is failing?

Common symptoms will be an engine stalling, inoperable starting, rough idling, poor acceleration, and a lit check engine light.

Instead of replacing it, can the crankshaft position sensor be cleaned?

The cleaning might help temporarily if this sensor is dirty or full of oil. However, the replacement shall be made if it is not serviceable because of certain breakage or wear and tear.

How much time is needed for crankshaft position sensor replacement?

Replacing a crankshaft position sensor generally takes 30 minutes up to 2 hours, depending on the position and accessibility of the sensor in the vehicle.

Can I bypass the crankshaft position sensor?

It is not possible to bypass a crankshaft position sensor since the sensor is part of the operations of the engine control unit or ECU. Without the sensor, the operation of the engine may not be possible or proper.

Will a bad crankshaft position sensor ruin my engine?

Yes, a malfunctioning sensor, if used continuously over a long period, may result in timing problems, misfires, and stress on other components of the engine, which could lead to permanent damage.

Do all cars have crankshaft position sensors?

Most modern vehicles have crankshaft position sensors as part of the electronic engine management system. Older, carbureted vehicles may not use this sensor.

Can a bad crankshaft position sensor trigger other error codes?

Yes, a failing sensor can set related codes for misfires, camshaft position sensor issues, or general engine timing problems.

How do you temporarily fix a crankshaft position sensor?

Temporary fixes include cleaning the sensor, securing loose wiring, or stabilizing it with electrical tape or zip ties. These are short-term solutions and should be followed by professional repair or replacement as soon as possible.