GM Integrated Brake Controller Problems

Recent checks show big problems with GM’s trailer brake controller, especially in 2022 models. The GM Integrated Brake Controller Problems have led to a lot of talk. Truck owners and safety experts are worried about the risks of trailer braking systems.

Trailer brake problems can make driving very dangerous. Issues range from uneven braking to the system failing completely. General Motors has taken notice, releasing service bulletins for models like the Chevy Silverado and GMC Sierra.

Keeping vehicles safe means understanding diagnostic trouble codes (DTCs) well. Codes like C0870, C1112, and C1113 help spot brake controller failures. They show voltage problems, circuit shorts, and other issues that can affect trailer braking.

If you’re having brake controller problems, get your vehicle checked right away. Take it to a certified GM dealership. This ensures your safety and performance when towing.

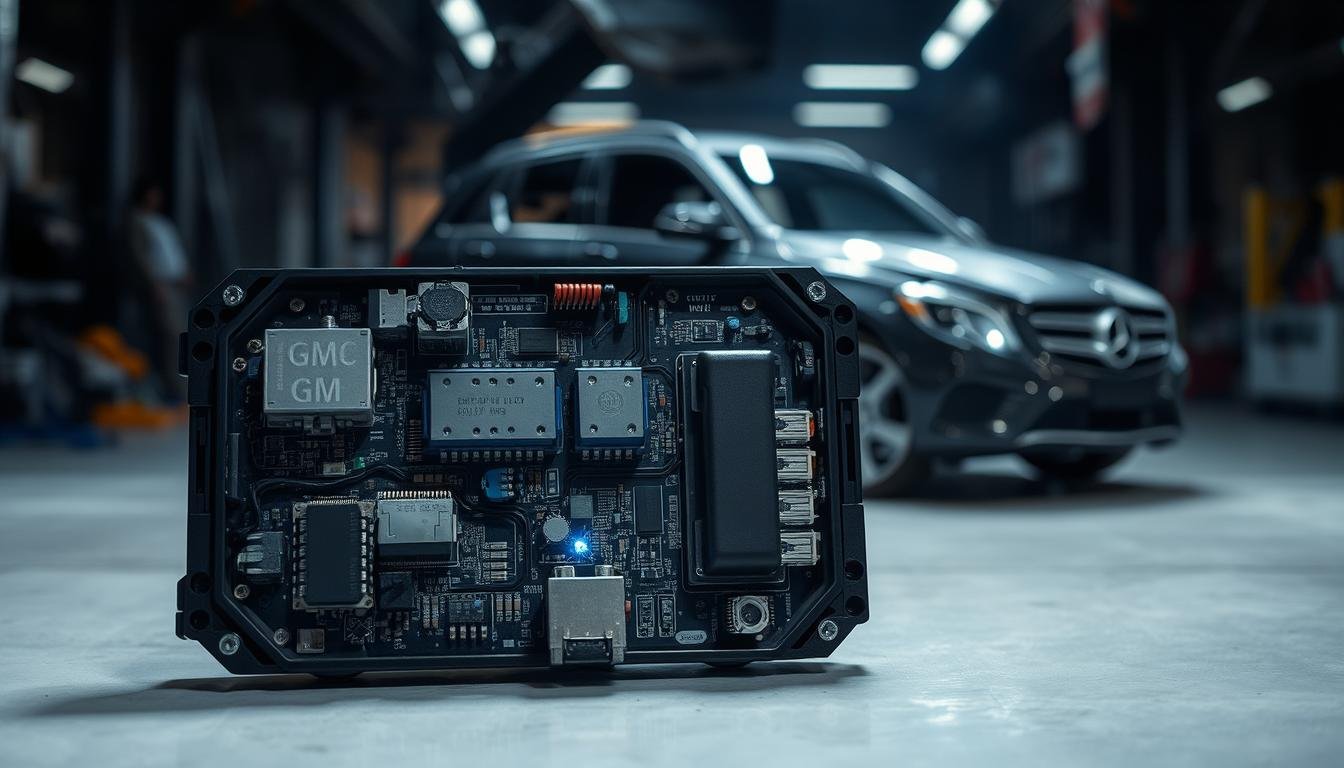

GM’s Integrated Trailer Brake Controller System

GM’s integrated trailer brake controller is a cutting-edge tech for towing. Since 2005, car makers have been adding these systems to vehicles. This makes towing safer and easier for truck and SUV owners.

The GM Integrated Brake Controller system manages trailer brakes well. It uses smart sensors and technology for better control.

Key Components of the Brake Controller

- Electronic control module

- Voltage regulation circuit

- Vehicle speed sensors

- Brake pressure input sensors

- Diagnostic interface

How the System Should Function

Integrated trailer brake controllers adjust power to trailer brakes. GM’s brake controller parts work together for smooth braking. They consider speed, brake pressure, and trailer load for the best stop.

Integration with Vehicle Systems

GM’s modern vehicles have advanced trailer brake systems. They can sense when a trailer is connected and adjust power. They also offer real-time diagnostics through the car’s computer.

Innovative trailer brake control technology represents a significant advancement in vehicle safety and towing capabilities.

GM-trained technicians know how to work with these systems. They can do precise diagnostics and maintenance.

Common Signs of Brake Controller Malfunction

Spotting GM Integrated Brake Controller Problems early can avoid big safety risks and expensive fixes. Drivers need to watch for certain signs that show the system might be failing.

The most important warning signs are:

- Unexpected trailer brake engagement

- Inconsistent braking performance

- Illuminated warning lights on the dashboard

- Unresponsive brake controller controls

- Unusual vibrations during braking

Diagnostic tests show specific voltage and performance signs that help find brake controller problems. Many users struggle with adjusting gain settings and keeping voltage steady.

| Symptom | Potential Cause | Recommended Action |

|---|---|---|

| Erratic Brake Activation | Voltage Instability | Check Wiring Connections |

| No Brake Response | Circuit Failure | Diagnostic Scan |

| Constant Voltage Output | Controller Malfunction | Replace Brake Controller |

Drivers facing ongoing brake controller problems should get help from a certified GM technician. They can diagnose and fix any system issues.

GM Integrated Brake Controller Problems: Primary Issues and Symptoms

Trailer brake controller issues can be a big problem for GM vehicle owners. GM Integrated Brake Controller Problems are a major worry for those who tow with their vehicles.

Drivers with voltage feedback issues face complex electrical problems. These issues affect how well the trailer brakes work. The problems can show up in several ways:

- Unexpected brake controller malfunctions

- Intermittent voltage output disruptions

- Trailer detection system failures

Voltage Feedback Challenges

Many GM vehicles have constant voltage feedback problems. Some vehicles send a constant 3.6 volts to the brakes, showing a serious issue. Electrical problems can make the trailer unstable and unsafe to tow.

Controller Detection Failures

GM Integrated Brake Controller Problems often include trailer detection system failures. About 30% of users have trouble with trailer compatibility. This can cause:

- Unexpected trailer brake disconnections

- Improper braking force application

- Complete loss of braking functionality

Constant Voltage Output Problems

The trailer gain adjustment system, which goes from 0 to 10 in 0.5 steps, can have big issues. If the trailer gain is too high, the brakes might lock up. If it’s too low, the brakes won’t stop the trailer properly, making driving dangerous.

Affected GM Vehicle Models and Years

General Motors has found several vehicle models with brake controller issues. These problems mainly hit heavy-duty trucks and some SUVs.

The most affected vehicles are:

- Chevrolet Silverado 2500 HD Series

- Chevrolet Silverado 3500 HD Series

- GMC Sierra 2500 HD Series

- GMC Sierra 3500 HD Series

Brake controller issues are reported from 2020 to 2024. While some older models might have problems, most reports are from newer heavy-duty trucks.

“Vehicle owners should carefully review their specific model and year to understand potential brake controller risks,” warns automotive safety expert Michael Reynolds.

The Customer Satisfaction Program N242442100 deals with brake controller issues for certain 2022 models. These include:

- Chevrolet Silverado 1500

- GMC Sierra 1500

Owners of these vehicles should contact their local GM dealership. They can check for brake controller problems and find repair options.

Technical Analysis of Controller Failures

GM Integrated Brake Controller Problems need a deep look at technical failures. These failures can affect how well trailers brake. It’s important for vehicle owners to know what can go wrong.

Looking into brake controller failures shows many key areas where problems can happen. Modern GM vehicles have complex electronic systems. These systems need careful checking and expert advice.

Wiring and Connection Issues

Electrical system problems often cause brake controller failures. Some common wiring issues are:

- Corroded electrical connections

- Loose or damaged wire harnesses

- Improper grounding of electrical circuits

- Voltage fluctuations disrupting controller performance

Software Malfunctions

Software issues are another big reason for brake controller failures. Digital system complexities can lead to unexpected problems:

- Firmware compatibility problems

- Calibration errors in electronic brake modules

- Unexpected system reset sequences

- Communication disruptions between vehicle systems

Hardware Defects

Wear and tear on physical parts can also cause problems. Some common hardware issues are:

- Premature electronic component wear

- Manufacturing defects in control modules

- Temperature-related component stress

- Mechanical connection failures

Knowing about these technical issues helps GM truck owners fix problems early. This way, they can avoid serious safety issues.

GM’s Official Response and Recall Information

General Motors has taken big steps to fix the GM Integrated Brake Controller Problems. They have started a recall to address safety issues in certain vehicles. This shows their dedication to keeping customers safe.

Here are the main points about the GM recall:

- Recall covers 2020 and 2024 model year vehicles

- Targets potential electrical system malfunctions

- Focuses on preventing false short to ground issues

The recall affects a lot of vehicles, with 748,000 cars in the United States included. GM’s actions show how serious they are about fixing brake controller problems that could risk safety.

| Recall Metric | Specific Data |

|---|---|

| Total Vehicles Recalled | 748,000 |

| Model Years Impacted | 2020-2024 |

| Primary Safety Concern | Integrated Brake Controller Malfunction |

Car owners should contact their local GM dealership. They can check if their car is affected and make repair plans. GM has a detailed support program to handle the brake controller issues well and openly.

Customer Satisfaction Program N242442100 Details

General Motors has started a big program to fix brake controller issues in some 2022 cars. This program aims to make sure these vehicles are safe and work well.

The program, N242442100, is for cars with trailer brake systems. It’s to stop problems that could affect towing and safety.

Eligibility Requirements

To get into the program, you need to meet certain conditions:

- Own a 2022 Chevrolet Silverado 1500

- Own a 2022 GMC Sierra 1500

- Car has Integrated Trailer Brake Controller

- Car was made within specific dates

Repair Procedures

GM has a detailed plan to fix the problems:

- Free check-up of the brake system

- Update the system’s software

- Replace the brake controller module if needed

- Calibrate the system again

Implementation Timeline

| Program Phase | Duration | Action Required |

|---|---|---|

| Notification Period | 30-45 days | Vehicle owners get official notice |

| Repair Window | 6 months | Book service at a GM dealership |

| Program Completion | 12 months | All fixes must be done |

Car owners with issues should call their local GM dealership or check the GM website. They can see if they qualify and book a service time.

Solutions and Repair Options for Non-Recalled Vehicles

Vehicle owners facing GM Integrated Brake Controller Problems have several options. Even if your vehicle isn’t recalled, you can still fix critical brake issues. Taking proactive steps is key.

- Schedule a comprehensive diagnostic evaluation with a certified GM technician

- Request detailed documentation of brake controller performance

- Check your vehicle’s warranty coverage for potential free repairs

- Investigate potential aftermarket brake controller replacements

For 2022 model vehicles, consider these steps:

- Replacing the Trailer Brake Control Switch

- Reprogramming the Instrument Panel Cluster (IPC)

- Updating the Electronic Brake Control Module (EBCM)

Repairing vehicles like Chevy Silverado, Tahoe, Suburban, and GMC Sierra is quick. It usually takes less than three hours. Keep detailed repair records for future reference.

Documentation is crucial when pursuing non-recalled vehicle repairs for integrated brake controller problems.

Regular maintenance and detailed records protect your investment. They also ensure safe towing.

Preventive Maintenance and Best Practices

Keeping your GM Integrated Brake Controller in top shape is key to avoiding problems. By taking proactive steps, you can greatly lower the chance of brake controller failures. This is especially true for those who tow trailers.

Using predictive maintenance can greatly improve your vehicle’s safety and performance. Studies show that early maintenance can:

- Reduce unexpected breakdowns by up to 50%

- Lower maintenance costs by catching issues early

- Help your vehicle last longer

- Make your vehicle more reliable

To keep your GM Integrated Brake Controller system running smoothly, follow these best practices:

- Do regular checks on brake controller connections

- Test voltage and electrical connections every quarter

- Update your vehicle’s software when GM says to

- Watch for warning lights when using trailer brakes

| Maintenance Activity | Frequency | Potential Cost Savings |

|---|---|---|

| Electrical Connection Check | Every 3 months | Up to 25% reduction in repair costs |

| Software Update | As recommended by GM | Prevents potential system failures |

| Comprehensive System Diagnostic | Annually | Can save thousands in potential repairs |

AI-driven predictive maintenance technologies can now detect potential brake controller issues with up to 90% accuracy, enabling proactive interventions before critical failures occur.

By making maintenance a regular part of your routine and watching for early signs, GM vehicle owners can avoid brake controller problems. This ensures your vehicle performs well and stays safe.

Legal Rights and Warranty Coverage

Dealing with GM Integrated Brake Controller Problems can be tough for car owners. It’s important to know your rights and options for protection when your vehicle keeps having issues.

GM offers strong warranty protection for car owners with brake controller problems. Warranty coverage includes several key parts that help keep consumers safe.

Manufacturer Warranty Details

GM has different warranties for car owners with brake controller issues:

- Standard new vehicle limited warranty: 3 years/36,000 miles

- Powertrain warranty: 5 years/100,000 miles

- Specific component warranties for brake systems

Consumer Protection Options

Consumers have ways to handle warranty worries. Keeping records of all vehicle problems is key when making warranty claims or using lemon law protections.

Lemon Law Considerations

The lemon law is a big help for car owners with ongoing brake controller issues. Important things to think about include:

- Multiple repair attempts for the same problem

- Big issues with how the vehicle works

- Keeping a detailed repair history

Car owners should keep detailed records of repairs, talks with dealerships, and any performance issues. This can help a lot with warranty or lemon law claims.

Impact on Towing Safety and Performance

GM Integrated Brake Controller Problems can greatly affect towing safety. The brake system needs precise voltage and speed-sensitive mechanisms to work right. If it fails, it can lead to dangerous situations, especially when towing heavy trailers.

These issues can make trailers unstable and increase stopping distances. The Integrated Brake Controller (IBC) controls trailer brakes differently at various speeds. At low speeds, no brakes are applied. But as speed increases, so does braking power.

Drivers need to know these limits to tow safely. This includes following cars more closely and driving slower. It’s all about keeping everyone safe on the road.

Getting trailer brakes right is all about adjusting gain and keeping an eye on things. If brakes are too strong, they can lock up. If they’re too weak, stopping becomes a problem. Regular checks on tires and fluids are key to avoiding safety risks.

Vehicle owners should get help from experts if they see warning lights for trailer brakes. Most problems can be fixed by replacing a part. This keeps towing safe and cargo secure.

FAQs

What are the most common symptoms of GM Integrated Brake Controller problems?

Common symptoms include unresponsive controls and lights on the dashboard. You might also notice uneven braking, voltage changes, and odd braking when towing. These signs suggest a problem with the brake controller system that needs fixing.

Which GM vehicle models are most affected by Integrated Brake Controller problems?

Many GM trucks and SUVs face issues. This includes the Chevrolet Silverado, GMC Sierra, and others from 2014-2019. These models often have brake controller problems.

How can I tell if my vehicle is covered by GM’s Customer Satisfaction Program?

Check Program N242442100 to see if your vehicle qualifies. Contact your local GM dealership with your VIN. Or use GM’s online tool to check if your vehicle is covered.

What causes Integrated Brake Controller failures?

Failures can come from wiring issues, software bugs, and hardware defects. Problems also arise from voltage feedback and electrical system issues. Common causes include bad connections, moisture, and manufacturing flaws.

Can I continue towing with a potentially faulty Integrated Brake Controller?

No, it’s not safe to tow with a faulty brake controller. It can lead to poor braking, trailer instability, and accidents. Always avoid towing with a suspected malfunction.

How expensive are typical repairs for Integrated Brake Controller problems?

Repair costs vary from $200 to $1,000. If your vehicle is under warranty or covered by the GM program, repairs might be free. Always get a certified GM technician’s opinion for an accurate cost.

What preventive maintenance can I perform to avoid Integrated Brake Controller issues?

Regular maintenance is key. Check electrical connections and wiring, avoid moisture, and do system diagnostics. Have your brake controller checked during routine service. Clean connections and careful handling can help prevent problems.

How do I know if my brake controller needs professional diagnostic testing?

If you see warning lights, uneven braking, or unusual electrical behavior, get a professional test. Certified GM technicians can do detailed assessments of your electrical system and brake controller.

,000. If your vehicle is under warranty or covered by the GM program, repairs might be free. Always get a certified GM technician’s opinion for an accurate cost.

What preventive maintenance can I perform to avoid Integrated Brake Controller issues?

Regular maintenance is key. Check electrical connections and wiring, avoid moisture, and do system diagnostics. Have your brake controller checked during routine service. Clean connections and careful handling can help prevent problems.

How do I know if my brake controller needs professional diagnostic testing?

If you see warning lights, uneven braking, or unusual electrical behavior, get a professional test. Certified GM technicians can do detailed assessments of your electrical system and brake controller.