Causes Behind the GM 6.6 Gas Problems

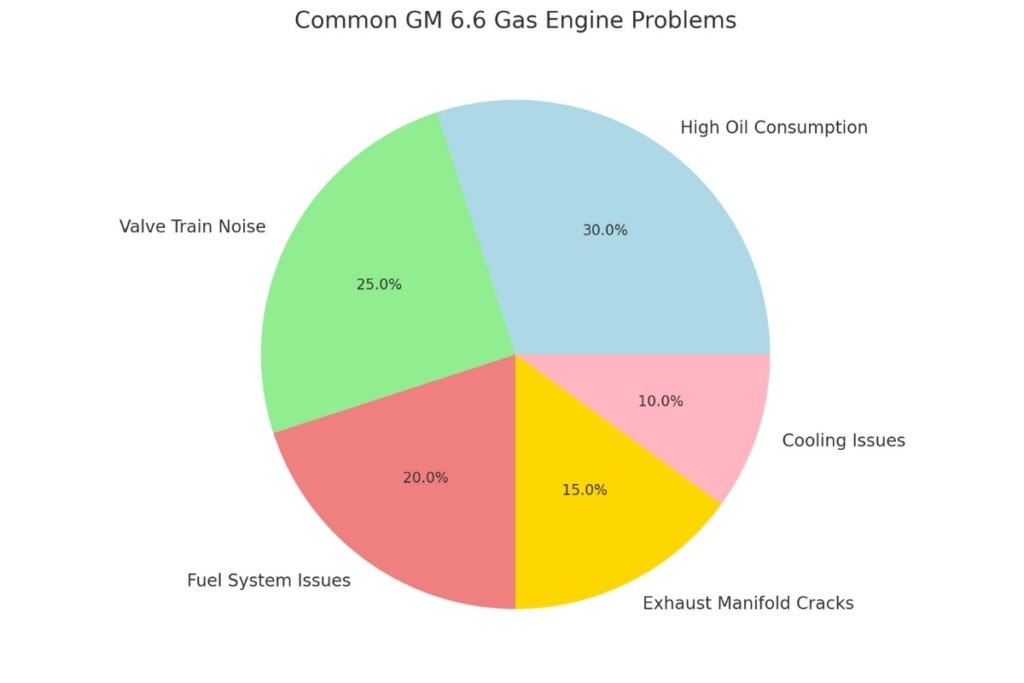

Common issues with the GM 6.6 gas engine include valve train noises, high oil consumption, fuel system failures, and even cracks in the exhaust manifold.

Fixing these GM 6.6 gas problems and early corrective action will avoid costly repairs that might result from such issues and help maintain reliable performance.

Whether one is putting this GM 6.6 gas engine to work for towing, hauling, or just around-town driving, knowing about these problems is vital to best keep it running at its finest.

GM 6.6 Gas Engine Specs

The GM 6.6 gas engine is a strong V8 powerhouse that’s developed to strike a critical balance of performance, reliability, and efficiency for a wide field of heavy-duty applications.

It was launched as a complement to its well-known diesel counterpart, offering an economic and versatile alternative to those in need of a powerful workhorse sans the additional maintenance of diesel engines.

Specifications and Applications

- Engine Type: 6.6-liter V8 gasoline engine.

- Power Output: Approximately 401 horsepower and 464 lb-ft of torque.

- Fuel System: It is installed with direct fuel injection for efficiency in fuel economy and power delivery.

- Construction: It is also equipped with a cast-iron block and aluminum cylinder heads to add to durability and heat dissipation.

| Specification | Details |

| Displacement | 6.6 liters (400.55 cubic inches) |

| Type | Naturally-aspirated V8 |

| Bore | 103.25 mm (4.065 inches) |

| Stroke | 98.0 mm (3.858 inches) |

| Compression Ratio | 10.8:1 |

| Horsepower | 401 hp at 5,200 rpm |

| Torque | 464 lb-ft at 4,000 rpm |

| Fuel Type | Regular unleaded gasoline (87 octane) |

| Valvetrain | 16-valve OHV (Overhead Valve) |

| Crankshaft | Forged steel |

| Connecting Rods | Forged powder metal |

| Oil Capacity | 8.0 quarts |

The 6.6L gas engine will be primarily applied to heavy-duty trucks, as well as to those vehicles intended for continuous towing and hauling. Such engines may feature in the Chevrolet Silverado 2500/3500 HD and GMC Sierra 2500/3500 HD of renowned make, serving commercial and personal purposes.

Strengths and Popular Features

High Torque for Towing: The 6.6-gas engine returns good torque, excellent in providing the ability to tow heavy gross weights while not sacrificing any performance in acceleration.

Cost-Effective Alternative: Standing up against the diesel engines, the GM 6.6 gas variant presents a truce in the way of purchase price and maintenance cost.

Advanced Fuel Injection: Direct fuel injection enhances fuel atomization, hence offering better combustion, power, and fuel efficiency.

Durability: It comes with a cast-iron block and is expected to last long, resilient to high-stress situations.

Smooth Performance: The engine is meant to give out a flawless drive from acceleration up to minimal lag.

The GM 6.6 gas engine was appreciated for an ideal combination of power, practicality, and reliability; no wonder it’s popular among those who need an able workhorse but do not want to tinker with a diesel.

6 Serious GM 6.6 Gas Problems

Despite its reputation for strength and durability, several issues have been reported by both owners and mechanics concerning this GM 6.6 gas engine.

Awareness of these issues will help owners of these engines take early measures that will be of help in maintaining the reliability and efficiency of the engine.

The following are some of the frequently encountered problems well described:

1. Fuel System Issues

Some owners have complained of fuel delivery problems, non-uniform fuel pressure, and faulty injectors. This can be manifested as poor engine performance with low output power and fuel economy.

Fuel system malfunction will cause an imbalanced lean or rich condition on the engine, causing partial misfires, rough idling, and, in worst cases, engine stalling.

2. Valve Train Noise

Noisy valve trains are sometimes reported by owners, which reveal a regular ticking or light tapping, but this happens usually at cold startups. Most of the time, this is normally because of lifters or poor pushrods.

If these sounds linger, it would appear that wear-out of parts is present, and if neglected, this could lead to more serious problems in the forms of damaged valves or poor performances of the engine.

3. Oil Consumption

It has also been reported by some owners to have higher oil consumption compared to what they have ever experienced. This will certainly require top-ups more frequently, perhaps more often, with frequent monitoring of its level. This condition can relate to worn piston rings or valve seals.

The excessive oil consumption may cause reduced lubrication, which in turn may increase the possibility of engine wear and overheating if not dealt with in time.

4. Exhaust Manifold Cracks

The exhaust manifold can crack due to large and extra heat cycles in it or even due to material stress. This can make them leak by way of exorbitant noise.

A broken manifold would lead to a reduction in the efficiency and power of the engine. This could also allow the fumes to escape into the car cabin, which is quite dangerous.

5. Faulty Spark Plug

With the high compression and resultant heat inside the engine, some owners have had to deal with premature wear and tear on the spark plugs or even outright misfiring.

Worn-out or burned spark plugs cause misfires, decreased acceleration, and poor fuel economy that consequently affects the overall reliability of the engine.

6. Cooling System Issues

In mostly hot climates, the cooling system may be stressed when the engine is under heavy loads; this can cause overheating.

If overheating of the engine is allowed, any resultant component damage will impair its performance and reliability, shortening its life and making serious problems-such as head gasket failure-probable.

All these shared problems would combine to render the GM 6.6 gas engine’s performance and reliability low. For instance, excess oil consumption and cooling system issues might lead to overheating of the engine, while valve train noise and spark plug problems result in loss of power and smoothness in running the engine.

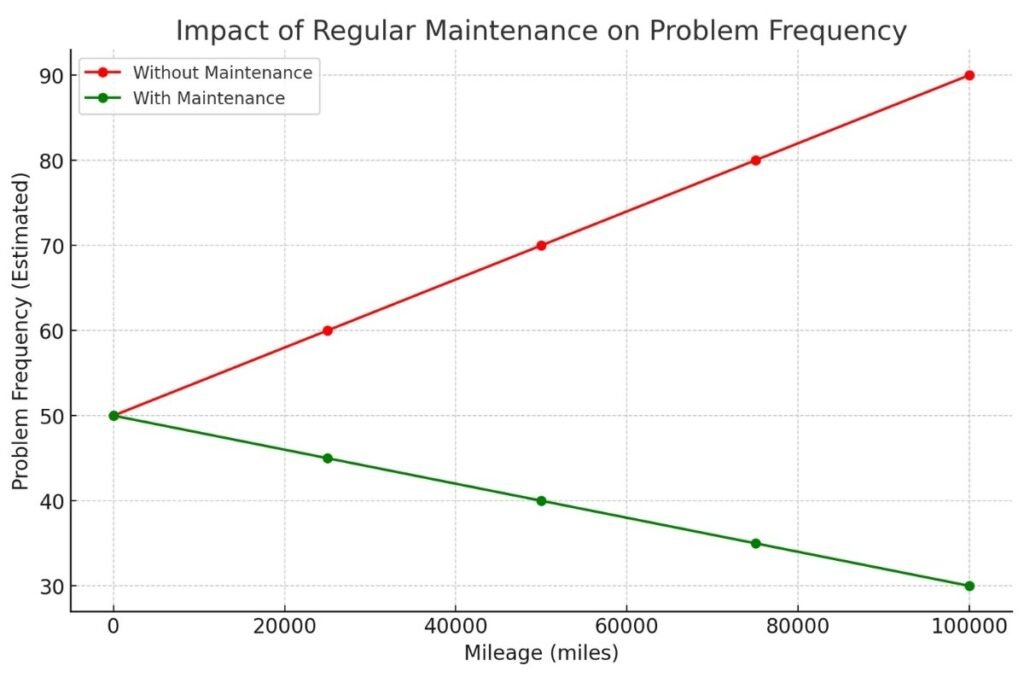

Dealing with early-stage issues and religious adherence to maintaining a schedule would save owners from further damage and ensure that the engine continues to perform well.

Causes of GM 6.6 Gas Problems

Figuring out the roots of some common problems with the GM 6.6 gas engine can help take precautionary measures and maintain the health of an engine upright.

The possible causes and some expert views concerning the mechanical and electronic problems causing the following are highlighted below:

Fuel System Problems

Fuel system malfunction is normally because of fuel injectors clogged or malfunctioning, improper fuel pressure, or a worn-out fuel pump. These may be catalyzed by contaminated fuel or low-quality gasoline.

Mechanics state that good-quality fuel used consistently and cleaning of the fuel system periodically reduces the possibility of an injector clogging and causing fluctuation in the pressure. On the other side, replacing fuel filters on time is very vital to avoid issues in fuel delivery.

Valve Train Noise

Noisy valve trains are normally due to inadequate lubrication, worn lifters, and/or weak pushrods. These may be due to deterioration in oil quality or missed oil changes.

Use the proper viscosity of oil as specified by the manufacturer. Follow the on-time oil change routine recommended by the owner’s manual. Running a low level or wrong viscosity of oil accelerates wear of all valve train parts, which encourages noise and additional damage.

Oil Consumption

The intake of high oil can arise with worn piston rings, defective valve seals, or some sort of malfunctioning Positive Crankcase Ventilation. Over a relatively high number of mileage or over time when it isn’t serviced much, that may be the case.

Consumption problems, if noticed early and the oil level is regularly checked, then it will save the engine from serious damage. Checking of the engine regularly along with using only high-quality oil will further reduce the possibility of excessive oil consumption.

Cracked Exhaust Manifold

Usually, this problem is caused by the repetitive expansion and contraction created by high cycles of heat. Over time, the continuing stress can cause fractures, especially when the material quality is not good, or if the vehicle has been subjected to heavy towing or working under continuous heavy load.

Minimizing heat generation will lessen the problem of overheating. The mechanics recommend frequent checks for exhaust leaks and the application of heat-resistant gaskets to alleviate the manifold from stress.

Spark Plug Issues

The high compression and heat inside the engine contribute to the preterm failure of spark plugs. Sometimes, incorrect selection of spark plug types or improper gaps may also lead to misfiring or poor engine performance.

These can be prevented by using only manufacture recommended spark plugs and making sure the correct gapping is present when the time for replacement arises. The ignition system must be checked periodically to see if early signs of misfires or degrading plugs can be found.

Cooling System Problems

An ignored cooling system may turn out to be inadequate under high-load and high-temperature conditions. The chances can be increased by problematic hoses, a bad radiator, or an inefficient water pump.

Experts suggest periodic flushing of coolant and checking of components within the cooling system. The professionals can avoid overheating issues by ensuring that coolant is at the right level as well as replacing old parts in advance.

Signs and Symptoms to Watch For

The thing with the GM 6.6 gas engine is to get early warning that something is wrong and nipping it in the bud rather than waiting for further damage to occur.

Ordinary signs to look for include:

1. Check Engine Light

Indication: The illumination of the check engine light is one of the most commonly usual causes for indicating that there is a problem. It could be as minor as a sensor issue or serious problems such as misfires or fuel system malfunctions.

Importance: Not heeding to this will only prolong the problem, and the light normally comes on to indicate an underlying problem to which immediate attention is necessary.

2. Unusual Noises

Indication: Knocking, tapping, or ticking sounds from the engine compartment might hint at problems with the valve train, a lack of proper lubrication, or component wear.

Importance: If these noises are caught early enough, they can save wear from transferring into more serious damage, such as problems to the valves or pistons.

3. Poor Fuel Economy

Indication: A noticeable drop in fuel economy may foreshadow such issues as fuel system inefficiencies, clogged injectors, or even misfiring spark plugs. Importance: It is very important to pay attention to fuel consumption and take measures to remedy the inefficiency in order not to be confronted with greater problems, such as engine misfires and rough idling.

4. Excessive Oil Consumption

Indication: In cases of frequent refills, this may be indicative of worn-out piston rings or valve seals.

Importance: Failure to take appropriate measures in case of oil consumption may result in improper lubrication, frictions, and overheating of the engine.

5. Visible Smoke from the Exhaust

Indication: The smoke from the exhaust may vary in color-wherein blue means that oil is burning inside, black would indicate that there is excess fuel, and white means coolant problems.

Importance: Knowing what the color of the smoke may mean should allow the driver to observe an early warning of troubles such as leaks either in oil or coolant.

6. Engine Overheating

Indication: Temperature increasing, or steam coming from the hood- Cooling system malfunction

Importance: Severe overheating may cause warping of various engine parts, as well as head gasket failure, so timely treatment is necessary

The sooner these symptoms are recognized, the less serious the damage will be. Early warning signs allow for small and manageable repairs, rather than costly overhauls.

Further, regular performance monitoring enables owners to recognize such symptoms and seek advice from qualified professionals to maintain the reliability and longevity of their GM 6.6 gas engines.

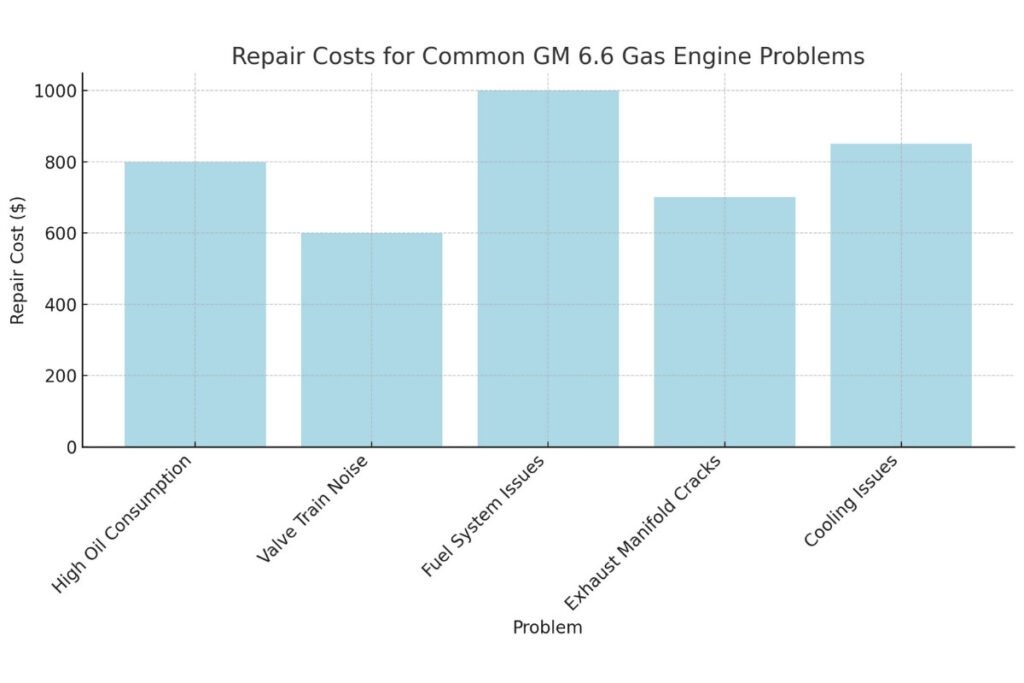

Estimated GM 6.6 Gas Engine Repair Costs

| Issue | Average Cost Range ($) | Description |

| Fuel System Repairs | $300 – $1,200 | Includes fuel injector or fuel pump replacement. |

| Valve Train Noise | $400 – $1,000 | Involves lifter replacement or valve adjustments. |

| Excessive Oil Consumption | $500 – $1,500 | May require new piston rings or valve seals. |

| Exhaust Manifold Crack | $600 – $1,200 | Repair or replacement of the exhaust manifold. |

| Spark Plug Replacement | $100 – $300 | Replacing spark plugs and ignition inspection. |

| Cooling System Repairs | $400 – $1,300 | Repairs include radiator, water pump, or hose replacements. |

FAQs

What Is The Problem With The GM 6.6 Gas Engine?

Among owners, some of the primary complaints included engines consuming too much oil, valve train noise, issues with fuel system, along with exhaust manifold cracks.

Early recognition of signs and symptoms of these helps to mitigate some of the issues.

How Reliable Is the GM 6.6 Gas Compared to the Diesel Version?

The GM 6.6 gas engine has normally been reliable; it’s just that it doesn’t have the same durability or torque of the diesel cousins.

In fact, the diesel versions would have greater towing capacity and longevity, plus be more suitable for heavy-duty applications.

What Maintenance Practices Can Prevent Problems in the GM 6.6 Gas Engine?

It must be taken care of with routine oil changes, good quality fuel, timely changing of the spark plugs, and regular checking of the fuel and cooling systems.

Most of the common problems can be prevented by following the routine maintenance schedule set by the manufacturer.

Does GM 6.6 Gas Engine Consume High Amounts of Oil Normally?

Some owners reported higher-than-expected oil consumption. While it’s normal to use some oil, this would mostly be a sign of underlying problems, like worn piston rings or valve seals, when one is always needing to add oil between changes.

What Should I Do When I Hear Valve Train Noise in My GM 6.6 Gas Engine?

Most valve train noises, such as ticking or tapping, are caused by a lack of oil. Worn items could also be involved.

It is highly recommended that for quick diagnosis and resolution, the engine be taken for professional inspection.