GM 4l60 Transmission Problems

The GM 4L60-E transmission is a key moment in automotive history. It was introduced in 1993 for trucks and SUVs, and later for passenger vehicles in 1994. It became one of the most mass-produced automatic transmissions ever.

Despite its widespread use, the 4L60E transmission has faced unique problems. Automotive enthusiasts and mechanics recognize it as a remarkable piece of engineering. Production ended in 2013, as demand moved to 5 and 6-speed transmissions.

Owners of vehicles with the 4L60E transmission need to know about potential issues. These issues can affect performance and longevity. Understanding this transmission is key to keeping your vehicle reliable.

From valve body complications to electronic control challenges, the 4L60E needs careful attention. Proactive maintenance is essential for optimal performance.

4L60E Transmission: Evolution and Specifications

The 4L60E transmission marked a big step in GM’s history. It was introduced in 1993 for large trucks and SUVs. It quickly became one of the most made transmissions in car history.

It replaced the 700R4, bringing new tech to GM’s cars. This made their cars better and more efficient.

- Electronic shift control system

- Four-speed automatic configuration

- Designed for rear-wheel-drive vehicles

- Production span from 1993 to 2013

The 4L60E had big improvements over old models. Electronic solenoids replaced traditional hydraulic shift controls. This made gear changes better and the car run smoother.

This change also helped cars use less fuel. It made GM’s cars more efficient and powerful.

Gear ratios for the 4L60E transmission were carefully planned:

- 1st Gear: 3.06:1 torque multiplication

- 2nd Gear: 1.44:1 reduction

- 3rd Gear: Direct drive (1:1 ratio)

- 4th Gear (Overdrive): 0.70:1 for enhanced fuel economy

The 4L60E was a big step for GM. It led to more advanced transmissions later on. These included 6-speed and 8-speed transmissions.

GM 4l60 Transmission Problems

The 4L60E transmission was a key part in General Motors cars from 1993 to 2014. However, it has its own set of problems. These issues can really affect how well your car runs and how long it lasts.

Spotting 4L60E transmission problems early can save you a lot of money. It can also prevent major breakdowns. The main things to watch out for are:

- Reverse gear functionality

- Shifting irregularities

- Electronic control system malfunctions

Reverse Gear Complications

Issues with reverse gear are common in the 4L60E transmission. You might hear grinding noises, experience delayed engagement, or even find that reverse won’t work at all.

Transmission Shifting Challenges

Shifting problems can cause big performance issues. They might be due to wear and tear, fluid problems, or issues with the electronic controls.

| Symptom | Potential Cause | Recommended Action |

|---|---|---|

| Harsh Shifting | Worn Clutch Packs | Transmission Rebuild |

| Slipping Gears | Low Fluid Pressure | Fluid System Inspection |

| Delayed Engagement | Solenoid Malfunction | Electronic Diagnostics |

Electronic Control System Failures

The 4L60E’s electronic control system is a weak spot. Solenoid failures can cause the transmission to act strangely. This might even lead to it shutting down completely.

Regular maintenance and catching problems early are key. Keep an eye on your fluid levels, get professional checks, and know what symptoms to look out for. This can help avoid expensive repairs.

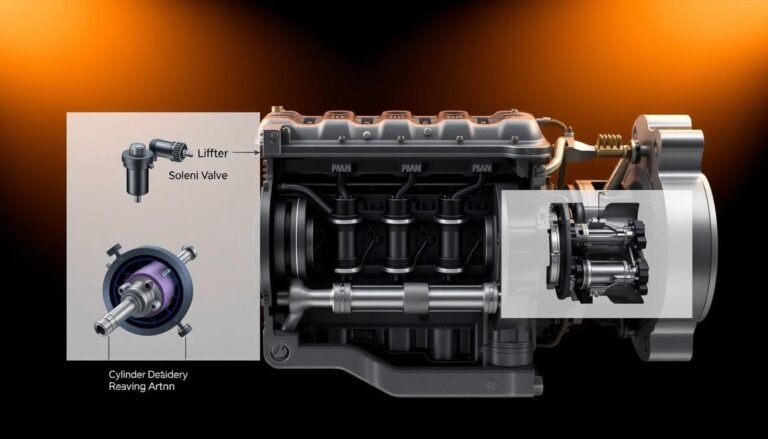

Critical Components and Failure Points

The 4L60E transmission is a complex system with many parts that can wear out and fail. Knowing which parts are most critical helps owners avoid big problems before they start.

GM transmission failure often happens in a few main areas:

- Drive shell integrity under extreme heat and pressure

- Solenoid system performance

- Planetary gear system durability

- Clutch pack and band wear patterns

The transmission’s mechanical vulnerabilities come from specific weak spots. For example, the drive shell faces a lot of stress, which can cause it to wear out early if not taken care of.

Transmission fluid quality is key to preventing parts from breaking down. Using high-quality synthetic ATF oil can help parts last longer by reducing friction and keeping them well-lubricated.

Key wear points include:

- Needle bearings showing signs of possible failure

- 2-4 band getting worse due to heat

- Solenoid system having trouble shifting

- Front pump bushing at risk of moving out of place

By doing regular maintenance and knowing where failures can happen, GM car owners can avoid expensive repairs and keep their cars running longer.

Valve Body Issues and Performance Impact

The valve body is key in the 4L60E transmission, controlling hydraulic pressure and gear shifts. Transmission hydraulic issues can hurt your vehicle’s performance and reliability.

4L60E valve body problems show up in certain ways. Mechanics and car owners need to know these signs:

- Pressure regulation challenges

- Solenoid performance degradation

- Hydraulic system integrity concerns

Separator Plate Complications

The separator plate in the transmission is very thin. This makes it prone to leaks between hydraulic circuits. Such leaks can cause unpredictable shifts and might even break the transmission.

Valve Body Wear Patterns

Looking at diagnostic data gives us clues about valve body health. The AFL valve, which controls solenoid pressure, works best at 80-115 psi. Wear on the valve can mess with solenoid pressure, leading to:

- Drivability problems

- Inappropriate shift valve stroking

- Compromised control pressure

Hydraulic System Failures

Transmission hydraulic issues show up in many ways. Problems with AFL feed pressure can stop the shift valve from working right. This might cause clutch failures. Vacuum tests during rebuilds help avoid warranty issues.

Knowing how the valve body works helps car owners fix problems early. This way, they avoid expensive repairs later on.

Torque Converter Complications and Solutions

The 4L60E transmission’s torque converter is key to its performance. GM transmission torque converter issues can make driving hard and unreliable.

Car owners often face specific 4L60E torque converter problems. These need careful checking and smart fixes. Common issues include:

- Cover flexion causing vibration during lockup

- Inadequate holding force when converter clutches engage

- Premature wear of internal components

- Unexpected performance limitations

Fixing these problems is tough because of the complex mix of mechanical and electronic parts. Mechanics suggest detailed transmission checks to find where the torque converter fails.

Getting help from a pro is key when problems keep coming back. Fixes can be simple replacements or big system changes. Costs can be $300 to $1,000, depending on the damage and needed fixes.

Car owners should watch for signs like unusual vibrations, bad shifting, or power loss. Quick checks and fixes can stop bigger problems and save money on repairs.

Input and Output Shaft System Failures

The 4L60E transmission needs its input and output shaft systems to work well. Knowing about these parts is key to avoiding big problems.

Transmission shaft systems are complex and need careful care. Stress, heat, and bad maintenance can harm these parts fast.

Input Shaft Damage Indicators

Spotting damage early can stop big transmission problems. Look out for:

- Unusual grinding noises during gear shifts

- Unexpected vibrations while driving

- Visible wear or scoring on the shaft surface

- Reduced transmission performance

Output Shaft Breaking Points

The output shaft is another key area for failure in the 4L60E transmission. Problems often come from:

- Excessive torque loading

- Repeated high-stress driving conditions

- Manufacturing inconsistencies

- Inadequate lubrication

Preventive Maintenance Strategies

Keeping up with maintenance can lower the chance of shaft failures:

- Regular transmission fluid checks

- Periodic professional inspections

- Avoid aggressive driving patterns

- Address early warning signs immediately

| Shaft Component | Common Failure Causes | Prevention Recommendation |

|---|---|---|

| Input Shaft | Excessive torque | Upgrade to performance-grade materials |

| Output Shaft | High-stress driving | Regular lubrication and inspection |

Knowing about these complex parts can help car owners avoid expensive fixes and keep their transmissions running longer.

Clutch Pack and Band Problems

The 4L60E transmission often faces issues with its clutch pack and band. These problems can really hurt a vehicle’s reliability. Many owners struggle with 4L60E clutch pack problems that make shifting rough and affect the transmission’s performance.

Critical areas of concern include:

- Thin intermediate band assembly

- Inadequate friction surface utilization

- Premature wear on transmission bands

- Heat-induced component degradation

Transmission band problems show up in several ways. The 2-4 band, for example, wears out fast because of heat and friction from heavy use. Short driving cycles make this wear worse by not letting the band get to the right temperature.

Performance enthusiasts and mechanics suggest a few upgrades to solve these problems:

- Replace the standard 2-4 band with a thicker, high-energy band

- Upgrade the 3-4 clutch pack for better durability

- Install aluminum accumulators to cut down on leaks

- Consider valve body modifications with special shift kits

By being proactive and upgrading, you can make your 4L60E transmission’s clutch packs and bands last longer. This prevents expensive repairs and keeps your vehicle running smoothly.

Transmission Maintenance and Prevention Strategies

Keeping your 4L60E transmission in good shape is key to your car’s long-term health. It helps avoid expensive fixes. Regular care can make your GM vehicle’s powertrain last longer.

Good GM transmission care means watching over your car closely. Experts say there are a few important steps to keep your transmission in top shape.

Fluid Maintenance Guidelines

Transmission fluid is vital for your 4L60E system. Here are some essential care tips:

- Check fluid levels every month

- Use top-notch synthetic ATF oil

- Change transmission fluid every 30,000-60,000 miles

- Install an auxiliary cooler for extra protection

Early Warning Signs

Spotting problems early can stop big issues. Keep an eye out for these signs:

- Unusual shifting patterns

- Delayed engagement

- Transmission slipping

- Unexplained performance drops

Performance Modifications

Upgrading can make your transmission more reliable. Here are some upgrades to consider:

| Modification | Benefit | Estimated Cost |

|---|---|---|

| Hardened Drive Shell | Enhanced wear resistance | $150-$250 |

| High-Energy Band | Improved heat resistance | $100-$200 |

| Inline Transmission Filter | Better fluid filtration | $50-$125 |

Using these GM transmission care tips can save you money and keep your car running well.

Performance Upgrades and Modifications

Performance enthusiasts looking to upgrade their 4L60E transmission have many options. The Sonnax 77733-06KA input housing kit is a top choice, fixing 3-4 clutch pack failures for about $200. This upgrade greatly boosts transmission reliability under stress.

Aftermarket kits like the Sonnax HP-4L60E-01 performance pack offer big improvements. They replace several parts for around $300, making shifts better and lasting longer. Experts suggest combining parts, like the Sonnax 74602-01K reaction shaft kit, for a stronger system.

Drivers on a budget can look at the 4L60E Transmission High Performance Rebuild Stage 5 WITH UPGRADES ZPAK. It costs about $500 and covers all needed upgrades. Adding an aftermarket deep pan increases oil capacity by 20-30%, helping the transmission last longer.

For those who want more power, making smart changes can turn the 4L60E into a high-performance machine. Upgrading with bigger kevlar bands, better sunshells, and special kits boosts its load capacity. This is great for heavy towing or racing.

FAQs

What are the most common problems with the GM 4L60 transmission?

Common issues include reverse gear problems and shifting irregularities. Electronic control failures and valve body complications are also common. Torque converter wear can cause hard shifts and slipping.

How can I identify early signs of 4L60E transmission failure?

Watch for unusual shifting patterns and fluid leaks. The check engine light turning on is a warning sign. Grinding noises and RPM fluctuations are also indicators of trouble.

Are 4L60E transmission problems expensive to repair?

Repair costs vary. Minor fixes can cost 0, while a full replacement can be ,500-,000. The price depends on the issue, vehicle, and the type of parts used.

Which GM vehicles commonly use the 4L60E transmission?

Many GM vehicles use the 4L60E transmission. This includes the Chevrolet Silverado, GMC Sierra, and Suburban. The Tahoe, Yukon, Camaro, and Corvette also use it from the mid-1990s to the early 2000s.

Can I prevent 4L60E transmission problems?

Yes, regular maintenance helps. Change transmission fluid every 30,000-60,000 miles. Use the right fluid and avoid harsh driving. Check for leaks and fix any issues quickly to avoid bigger problems.

What causes valve body issues in the 4L60E transmission?

Valve body problems often come from dirty fluid and wear. Debris and heat can also damage it. A damaged separator plate can cause shifting issues, and worn parts can lead to pressure problems.

How long do 4L60E transmissions typically last?

With care, a 4L60E can last 150,000 to 200,000 miles. But, driving conditions, maintenance, and vehicle use can affect its life.

Are there performance upgrades available for the 4L60E transmission?

Yes, you can upgrade with aftermarket parts. Improved valve bodies, better torque converters, and performance kits can enhance durability and handle more power.

What are the most critical components that fail in a 4L60E transmission?

Key parts include the valve body, torque converter, and shafts. Clutch packs and the electronic control unit are also prone to failure. These can lead to big performance issues if they break.

Can I rebuild a 4L60E transmission myself?

Rebuilding is possible but complex. It needs special tools and knowledge. Unless you’re very skilled, it’s best to let a professional do it for reliability and proper function.