Chevy 5.3 Ground Locations

Did you know up to 80% of car electrical issues come from bad ground connections? For Chevy 5.3 engines, knowing where these connections are is key. It helps keep your car running well and stops electrical problems.

Grounding is the heart of your car’s electrical system. In Chevy 5.3 engines, these spots are where electrical current moves safely and efficiently. They keep your car’s electrical systems working right.

Good ground connections are more than just tech details. They prevent electrical failures, protect your car’s electronics, and keep your Chevy 5.3 running at its best. Every ground point, from the engine to the battery and transmission, is important for your car’s electrical health.

This guide will show you the important ground locations in Chevy 5.3 engines. You’ll learn how to keep your car’s electrical system in top shape. Whether you love cars or like to fix them yourself, you’ll find useful tips to keep your Chevy running smoothly.

Importance of Proper Ground Connections

Ground connections are key to your Chevy 5.3’s electrical system. They make sure electrical current flows well and safely. This keeps your vehicle’s electronics working right and performing at their best.

Your vehicle’s electronics need strong ground connections to work right. Chevy trucks need good ground connections to keep their electrical systems safe and working well.

Impact on Vehicle Electronics and Performance

Ground connections affect your vehicle’s performance a lot. Bad grounding can cause big electrical problems. Important ground spots in Chevy trucks include:

- Firewall connections

- Door hinge locations

- Battery tray ground points

- Fuel filler neck

- Spare tire hoist bracket

- Areas under passenger and driver seats

Common Symptoms of Ground Issues

Spotting ground problems early can save you money. Look out for these signs:

- Flickering headlights

- Erratic gauge readings

- Unexplained voltage fluctuations

- Intermittent electrical component failures

Safety Considerations for Ground Maintenance

Keeping ground connections in check is vital for safety. Experts say to check ground wires yearly, or every six months if you drive in tough conditions. Cleaning and greasing connections can really help your electrical system. It can also stop electrical fires.

A well-maintained ground system is your vehicle’s first line of defense against electrical failures.

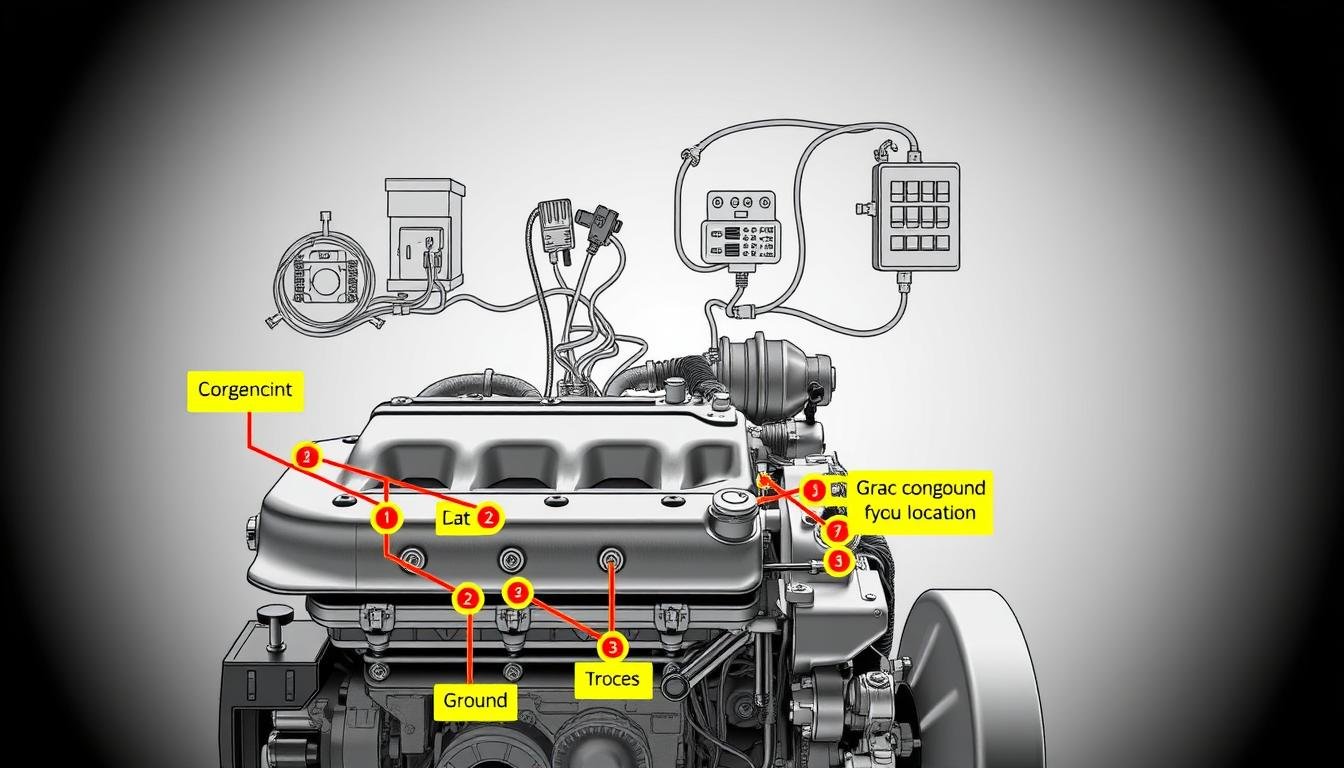

Primary Ground Points on Chevy 5.3 Engines

Knowing where the Chevy 5.3 ground points are is key for a good electrical system. These points are where the electrical flow starts and stops. They help avoid electrical system failures.

The Chevy 5.3 engine has important ground points for electrical system health. These points are placed to spread electrical current well across the vehicle’s systems.

- Engine Block Ground Connection

- Chassis Ground Point

- Battery Negative Terminal Ground

- Powertrain Control Module (PCM) Ground

It’s vital to keep these primary ground points in good shape to avoid electrical problems. Corrosion, loose connections, or damaged ground points can cause big electrical system issues.

| Ground Point Location | Primary Function | Potential Issues |

|---|---|---|

| Engine Block | Main electrical system ground | Corrosion, oxidation |

| Chassis | Vehicle-wide electrical ground | Loose mounting, rust |

| Battery Negative | Primary power distribution ground | Terminal corrosion, weak connection |

Regular checks on these Chevy 5.3 ground locations can stop electrical problems. Mechanics say to check these points during routine maintenance. This keeps the electrical system running smoothly.

PCM Ground Location and Maintenance

The Powertrain Control Module (PCM) ground is key in the Chevy 5.3 electrical system. It needs careful attention for the best vehicle performance. This helps avoid electrical problems.

Knowing where the PCM ground is and how to maintain it is important. Chevrolet 5.3 grounds are placed to improve electrical system efficiency.

Replacing and Relocating PCM Ground

When dealing with PCM ground issues, follow these steps:

- Check the ground connection for corrosion or damage

- Make sure connections are clean and tight

- Use the right wire gauge for good electrical flow

- Check the ground strap before replacing it

Testing PCM Ground Connectivity

Good PCM ground maintenance needs precise diagnostic methods:

- Use a multimeter to test ground resistance

- Check voltage drop across ground connections

- Look for signs of electrical interference

- Inspect wire continuity and connection points

Common PCM Ground Issues

Potential PCM ground problems can show in different ways:

- Intermittent electrical system failures

- Unexplained sensor malfunctions

- Erratic engine performance

- Check engine light activation

Regular PCM ground maintenance prevents expensive repairs. It keeps your Chevy 5.3 running well. Regular checks and quick action are essential for a strong electrical system.

Frame Ground Points and Their Functions

Knowing where to find Chevy 5.3 ground locations is key for your car’s electrical health. Frame ground points are essential for electrical systems. They make sure the current flows right across your vehicle.

Frame ground points on Chevy 5.3 engines are very important for electrical system health. They help manage electrical current. This prevents voltage problems.

- Primary frame ground locations typically include:

- Battery negative terminal ground connection

- Engine block to frame ground point

- Transmission ground connection

- Chassis electrical system ground

Voltage measurements give us important info about ground point performance. Keeping them in good shape can lower electrical resistance. This boosts system function.

| Ground Point Location | Typical Voltage Drop | Recommended Action |

|---|---|---|

| Negative Battery Post | 1.25 volts | Clean and inspect connections |

| Motor Ground | 1.08 volts | Check cable integrity |

| Battery Terminal | 0.65 volts | Replace if corroded |

Keeping up with ground point maintenance can stop electrical system failures. It also boosts your Chevy 5.3’s performance. Regular checks and cleanings of frame ground points ensure reliable connections. This keeps your vehicle running well.

Expert mechanics say to check ground connections during routine maintenance. This prevents electrical problems.

Engine Block Ground Connections

Proper engine block ground connections are key for your Chevy 5.3 engine’s electrical performance. These spots are important for a smooth electrical system and avoiding electrical problems.

It’s important to pay close attention to the Chevy 5.3 ground locations for the best electrical system function. Experienced mechanics suggest using multiple strategic grounds for full electrical connection.

Proper Installation Techniques

Here are the key steps for installing engine block ground connections:

- Clean all connection points well

- Use high-quality, corrosion-resistant hardware

- Make sure connections are tight and secure

- Choose the right gauge wire for engine block grounds

Corrosion Prevention Methods

Stopping corrosion is vital for reliable engine block ground connections. Here are some effective methods:

- Apply dielectric grease to connections

- Use stainless steel or brass hardware

- Regularly check and clean ground connection areas

- Think about using anti-corrosion washers

Voltage drop tests can show if there are ground connection issues. If you see more than 0.2 volts of drop, it’s a sign of a problem that needs fixing in your Chevy 5.3’s electrical system.

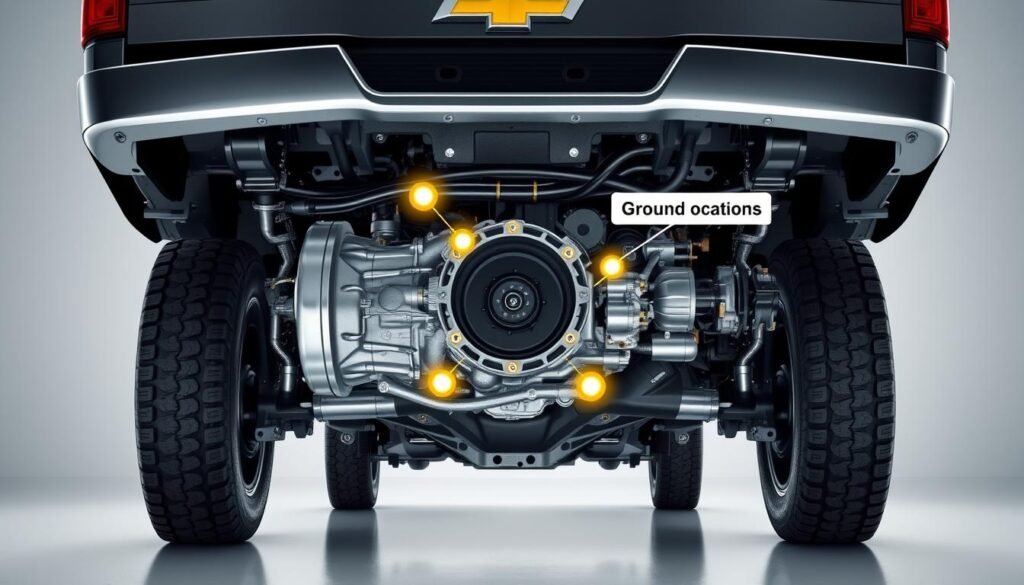

Transmission Ground Points

Knowing about transmission ground points is key for your Chevy 5.3’s electrical health. These spots are vital for keeping the electrical flow smooth. They help avoid system failures that could hurt your vehicle’s performance.

Transmission ground points do a lot for your Chevy 5.3’s electrical system:

- They give a stable path for transmission control modules.

- They cut down electrical resistance in important parts.

- They stop electrical interference and signal problems.

- They help your vehicle’s electronics work better.

Common Chevy 5.3 transmission ground spots are found in key places, like:

- Transmission control module mounting area

- Nearby chassis connection points

- Engine block interface zones

- Wiring harness attachment regions

Checking transmission ground points often can stop electrical troubles. Technicians say to look for:

- Corrosion buildup

- Loose connections

- Visible wire damage

- Potential short circuit risks

Keeping transmission ground points in good shape is essential. It ensures your Chevy 5.3’s electrical system works well. This can also save you from expensive repairs.

Battery Ground Cable Layout and Specifications

The battery ground cable is key to Chevy 5.3 engines’ electrical systems. It ensures top performance and avoids electrical issues. Knowing the layout and specs is vital for keeping your vehicle running well.

Getting the Chevy 5.3 ground locations right is important. Many owners don’t see how critical ground connections are. This can cause big problems with the electrical system.

Big Three Upgrade Process

The Big Three upgrade boosts electrical system performance. It focuses on three main connections:

- Battery to engine ground

- Battery to chassis ground

- Alternator to battery ground

For this upgrade, #2 ultra flex welding cable is often used. It offers great conductivity and cuts down voltage drop.

Cable Size Requirements

Choosing the right cable size is key for the Big Three upgrade. Here are the specs you need:

| Vehicle Type | Recommended Cable Size | Primary Application |

|---|---|---|

| Street Performance | #2 AWG | Moderate electrical demands |

| High Performance | #0 AWG | High electrical load vehicles |

| Racing Applications | #00 AWG | Extreme electrical requirements |

Pro tip: Always ensure proper cable termination and use high-quality, corrosion-resistant connectors during your battery ground cable upgrade.

Diagnosing Ground-Related Electrical Issues

Fixing electrical problems in Chevy 5.3 engines needs a careful plan. Finding ground connection issues is key. This keeps your car’s electrical system working right and stops big problems.

Spotting signs of ground-related electrical issues is the first step. Watch for these signs:

- Flickering dashboard lights

- Erratic gauge readings

- Unexpected voltage fluctuations

- Intermittent electrical component failures

Start by checking important Chevy 5.3 ground spots. Look at the firewall, battery tray, and chassis connection points. A good check can show corrosion, loose wires, or damage that hurts your car’s electrical system.

Experts say to follow a detailed check-up plan:

- Look at ground wire connections closely

- Use a multimeter to test ground point continuity

- Check for corrosion or damage

- Clean and tighten ground connections

- Make sure the electrical system works well after fixing

Keeping up with maintenance helps avoid big electrical problems. Regular checks of ground connections can lower the chance of sudden electrical failures. This keeps your Chevy 5.3 running smoothly.

Ground Distribution Circuit Overview

Understanding the Chevy 5.3 ground distribution circuit is key for your vehicle’s electrical health. These systems help power flow smoothly and avoid electrical issues.

The ground distribution circuit is the heart of your Chevy truck’s electrical system. It connects all the electronic parts and keeps the power flowing right. Knowing where the grounds are is vital to avoid power drops and electrical problems.

Circuit Mapping Essentials

Mapping out the circuit is a detailed job. You need to:

- Find the main ground points

- Follow the connection paths

- Check the resistance levels

- Look for corrosion or damage

System Integration Points

Important spots in the ground circuit include:

| Location | Function | Typical Resistance |

|---|---|---|

| Engine Block | Primary Ground Connection | < 0.5 ohms |

| Chassis | Secondary Ground Path | < 1.0 ohms |

| Battery Negative Terminal | Central Grounding Hub | 0 ohms |

Keeping these spots in good shape is essential for your Chevy 5.3’s electrical system. It helps avoid system failures.

Ground System Maintenance Schedule

Keeping your Chevy 5.3’s ground system in check is key for top-notch performance and avoiding electrical problems. Regular checks and proactive care can dodge expensive fixes and sudden breakdowns.

Having a set maintenance plan for Chevy 5.3 ground spots is vital for your vehicle’s electrical health. Experts suggest these maintenance times:

- Every 6 months: Full ground connection check-up

- Annually: Deep clean and corrosion scan

- During major services: Detailed ground system test

Focus on these areas during maintenance:

- Battery ground cable connections

- Engine block ground points

- Powertrain Control Module (PCM) ground spots

- Frame ground connection points

“Preventive maintenance is the key to long-lasting vehicle electrical performance.”

When you do maintenance, watch for corrosion, loose connections, or wear. Use electronic contact cleaner on contact points and make sure connections are tight. For Chevy 5.3 ground spots, apply dielectric grease to stop corrosion and keep electrical flow smooth.

Stick to a regular maintenance schedule for better electrical reliability and to avoid performance problems.

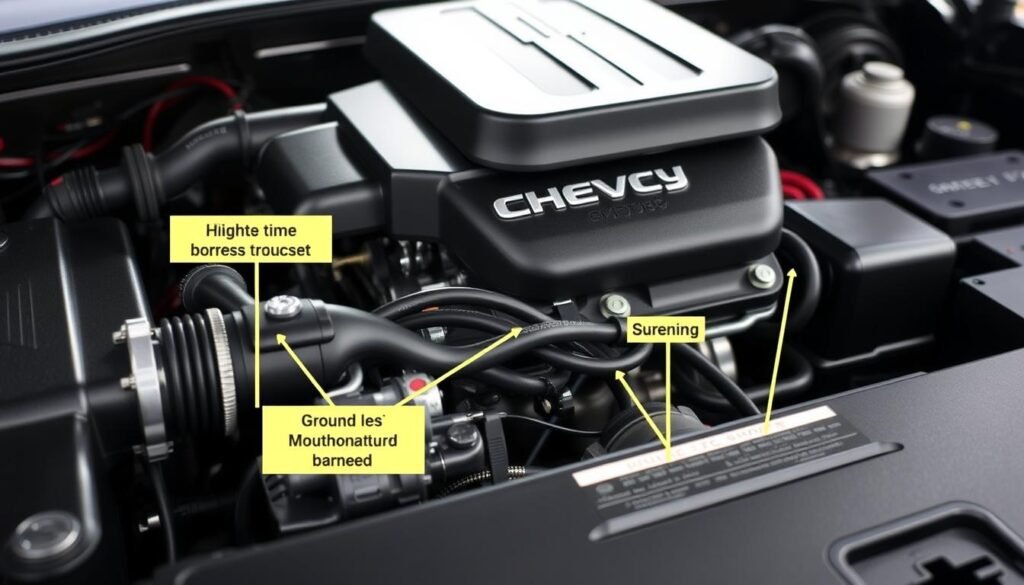

Upgrading Ground Connections for Better Performance

Improving ground connections in your Chevy 5.3 can make a big difference. It’s all about choosing the right wire and installing it correctly. Experts say using 0 gauge wire is best for ground paths. This helps keep the electrical system stable and efficient.

The “Big 3” upgrade is key for Chevy 5.3 ground locations. You need to replace the battery, alternator, and engine block wires with heavy-duty ones. Using #2 ultra flex welding cable is a smart choice. It boosts conductivity and cuts down electrical resistance.

When upgrading ground connections, pay close attention to the details. Technicians recommend using external star washers for better connections. Make sure to clean the ground points well and test them with a digital multimeter. This can fix issues like flickering lights and audio problems.

Keeping voltage drop low is vital. Aim for no more than 0.5 volts, ideally 0.2 to 0.3 volts. Spending time on quality upgrades can greatly improve your Chevy 5.3’s electrical system and performance.

FAQ

What are ground locations in a Chevy 5.3 engine?

Ground locations are key spots for electrical connections. They help ensure the vehicle’s electrical systems work right. In a Chevy 5.3 engine, these spots are on the engine block, frame, PCM, and transmission.

What are the signs of bad ground connections in my Chevy 5.3?

Look out for flickering dashboard lights and electrical issues that come and go. If starting your car is hard, or if your battery drains fast, it’s a sign. Also, unexpected voltage changes are a warning.

Where is the main PCM ground located on a Chevy 5.3 engine?

The PCM ground is near the ECU, often on the firewall or engine area. The exact spot can change with each model year. Always check your service manual for the right spot.

How often should I inspect my vehicle’s ground connections?

It’s good to check them during regular car maintenance. Do this every 12,000 miles or once a year. Look for corrosion, loose connections, or wear that could affect how well your car works.

Can I upgrade my Chevy 5.3’s ground connections myself?

Yes, you can upgrade them with high-quality cables like #2 ultra flex welding cable. But if you’re not sure about electrical work, it’s safer to get a professional mechanic to do it right.

What causes ground connection problems in Chevy 5.3 engines?

Problems can come from corrosion, loose connections, damaged cables, or oxidation. Poor installation can also cause issues. Things like moisture, road salt, and changing temperatures can make these problems worse.

How do ground connections affect vehicle performance?

Good ground connections keep electrical flow stable. They help electronic parts talk to each other right. This prevents voltage drops and keeps your car’s electronics working well.

What’s the “Big Three” ground upgrade?

The “Big Three” upgrade means swapping out the main ground cables. You replace the ones from the battery, alternator, and chassis with better ones. This makes your car’s electrical system more efficient and reduces resistance.

How can I test my Chevy 5.3’s ground connections?

Use a multimeter to check resistance and look for corrosion or damage. Do continuity tests too. If you’re not sure, a mechanic can do a full check.

Are ground connection issues dangerous?

Ground connection problems aren’t life-threatening right away. But, they can cause electrical failures and even fire risks. It’s best to fix them quickly to avoid problems.