GM 5.3 Engine Lifter Problems

The GM 5.3 engine lifter issues are a big challenge for General Motors. They affect many vehicle models over several years. Specific engine designs show ongoing problems with lifter performance. This is especially true for V8 engines with Active Fuel Management (AFM) systems.

GM vehicle owners face many issues, like ticking noises and reduced engine performance. They also see the check engine light turn on unexpectedly. These signs often point to deeper mechanical problems that could cost a lot to fix.

Vehicle owners with GM 5.3 Engine Lifter Problems need to watch for early signs. The complexity of these issues highlights the need for regular maintenance and expert checks. This helps avoid expensive engine damage in the long run.

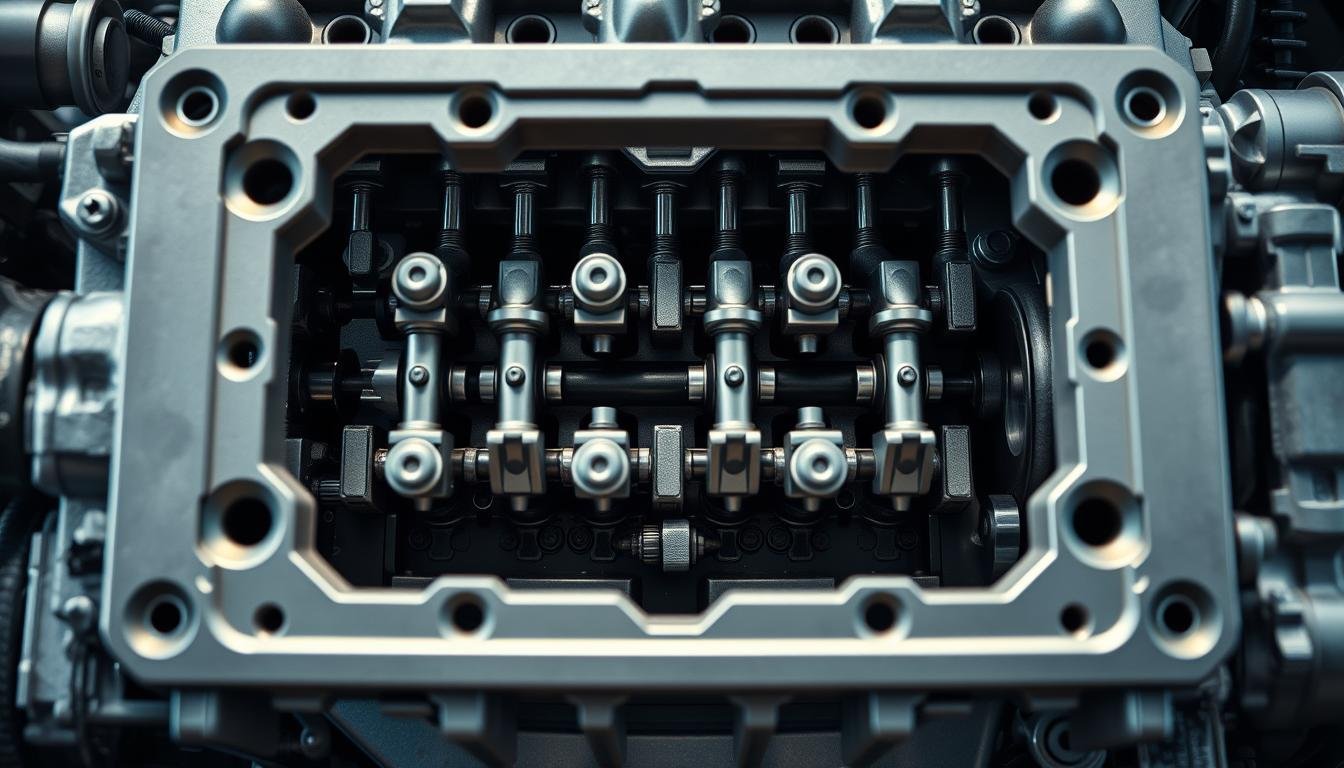

GM 5.3 Engine Architecture

The GM 5.3 engine is a big step in car engineering. It mixes advanced design with strong performance. It’s a key part of GM’s lineup, especially in trucks and SUVs. Knowing how it works helps us understand lifter problems that might happen.

The engine’s design shows years of mechanical improvement. Lifters are key in making the engine run well. They help the camshaft and valves work together smoothly.

Key Components of the Lifter System

The lifter system in GM 5.3 engines has many parts:

- Hydraulic roller lifters

- Camshaft interface mechanisms

- Precision-engineered valve train components

- Oil pressure-dependent activation systems

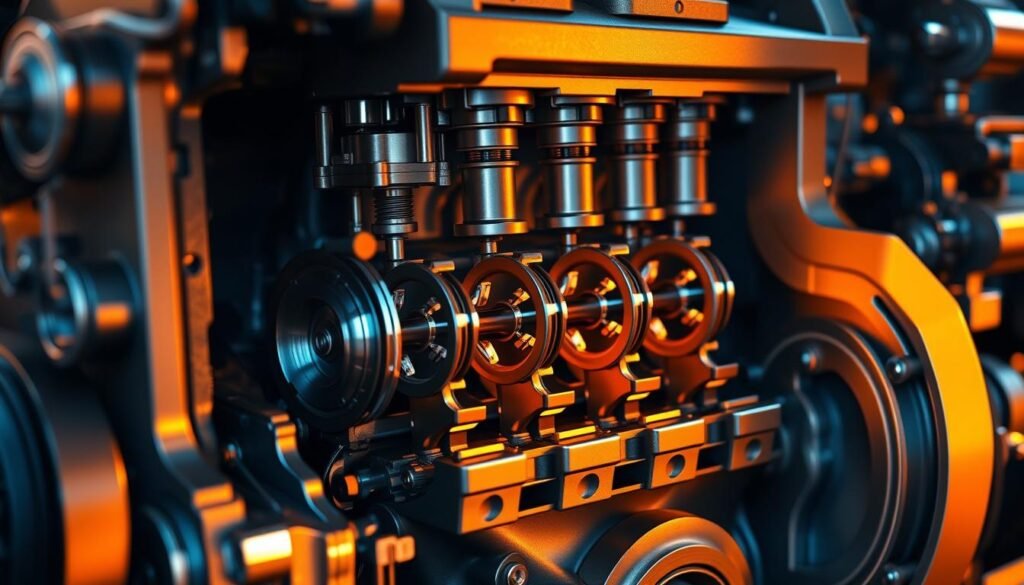

Engine Design Evolution Through Years

GM’s engine design has changed a lot over time. The LS engine family started in 1997. The first LS1 had 345 horsepower. Later models got even better, improving both power and reliability.

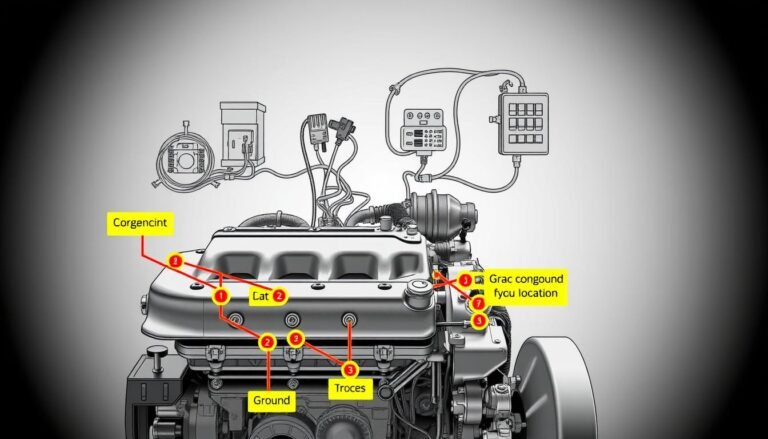

Critical Operating Mechanisms

Problems with the GM 5.3 engine lifters often come from how they work. About 15% of users face these issues. Fixing them can cost between $1,500 and $3,000. These problems usually happen between 100,000 to 150,000 miles.

“Understanding the engine’s architecture is the first step in preventing potential lifter failures.” – Automotive Engineering Insights

Knowing the engine’s design helps owners spot and fix problems early. This way, they can avoid bigger mechanical issues later on.

Common Signs of Lifter Failure in GM 5.3 Engines

GM 5.3 Engine Lifter Problems show up in several key warning signs. These signs are important to catch early. This helps avoid big engine damage and costly fixes.

Drivers with GM 5.3 engine lifter issues often hear certain sounds. These sounds hint at possible engine trouble:

- Persistent ticking or tapping noises during engine startup

- Unusual knocking sounds during acceleration

- Rough engine idling

- Noticeable reduction in overall engine performance

- Illuminated check engine light

Lifter problems can get worse fast. A small noise can quickly turn into big engine failures. This can harm the whole engine’s work.

| Symptom | Potential Severity | Recommended Action |

|---|---|---|

| Persistent Ticking Noise | Low to Moderate | Immediate Professional Inspection |

| Engine Misfires | High | Comprehensive Diagnostic Evaluation |

| Reduced Power Output | Moderate to Critical | Urgent Mechanical Assessment |

Owners of GM 5.3 engines should keep up with regular maintenance. They should also act fast if their engine acts strangely. Waiting too long can lead to very expensive fixes and even engine failure.

Professional mechanics say lifter issues don’t fix themselves. They need quick, expert help.

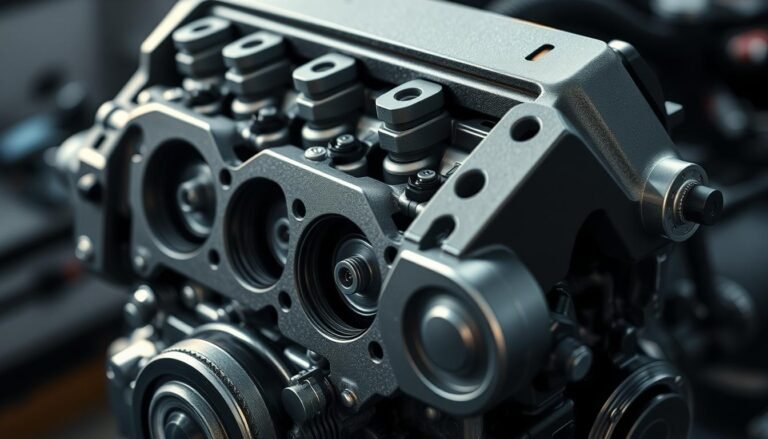

GM 5.3 Engine Lifter Problems: Root Causes and Analysis

The GM 5.3 engine faces big issues with lifter performance. These problems come from complex metal and design issues. Knowing these causes is key for car owners and mechanics to fix and prevent engine problems.

Metallurgy and Material Concerns

GM 5.3 engine lifter problems often come from metal issues. The investigation found several material problems:

- Surface defects in connecting rod bearing caps

- Micro shrinkage pores that weaken the structure

- Potential flaws in cast nodular iron manufacturing

Cast nodular iron, used since the 1990s, has its challenges. It’s strong and easy to machine but can have tiny flaws. These flaws can hurt engine performance over time.

Design Flaws Contributing to Failures

Several design parts lead to GM 5.3 engine lifter problems:

- Potential manufacturing tolerances in lifter production

- Inadequate lubrication pathways

- Sensitivity to operational variations

The suspect lifter window in 2021 truck models showed big manufacturing issues. Dealers had to replace all lifters to fix the problem.

Oil System Impact on Lifter Performance

The engine’s oil system is key for lifter function. Problems include:

- Oil aeration causing seal damage

- Less efficient lubrication

- More friction and wear

Warranty analysis shows lifter failures often happen in the first 8,000 miles. This points to design challenges.

To fix these problems, we need to understand material science, engineering, and how the GM 5.3 engine works.

Impact of Mileage on Lifter Performance

Mileage is key in how well GM 5.3 Engine lifter systems work. As cars get older, the chance of lifter problems grows. The Active Fuel Management (AFM) system makes things worse by speeding up wear and failure.

Things that affect lifter performance as mileage goes up include:

- Oil contamination and degradation

- Increased friction and wear on lifter components

- Accumulation of engine deposits

- Reduced lubrication efficiency

Big mileage marks for lifter troubles are between 70,000 and 125,000 miles. Signs get clearer as engines hit these points. Common signs include:

- Intermittent chirping or ticking sounds

- Reduced engine performance

- Check Engine light activation

- Cylinder compression loss

| Mileage Range | Potential Lifter Issues | Recommended Action |

|---|---|---|

| 0-50,000 miles | Minimal risk | Regular maintenance |

| 50,000-100,000 miles | Increased wear potential | Enhanced monitoring |

| 100,000-150,000 miles | High risk of lifter failure | Comprehensive inspection |

Preventive care is the best way to avoid GM 5.3 Engine Lifter Problems. Keeping up with oil changes and using the right oil helps a lot. Also, catching early signs can save your engine and avoid expensive fixes.

Latest Updates for 2023 Models and Lifter Modifications

General Motors is tackling the GM 5.3 Engine Lifter Problems head-on. They’ve made key updates for 2023 models. These changes aim to boost the V8 engine’s reliability and performance.

Engineering Improvements

GM has worked hard to fix lifter issues with new designs. They’ve made several important changes. These include:

- Enhanced lifter materials with improved durability

- Refined valve train component tolerances

- Updated engine control module software calibrations

- Reinforced lubrication pathways for better lifter performance

Manufacturer Responses

GM has taken steps to help owners of affected vehicles. They now offer:

- Extended powertrain coverage for lifter-related repairs

- Comprehensive diagnostic protocols for early issue detection

- Enhanced dealer training on lifter system maintenance

Technical Upgrades

The 2023 models have seen major technical upgrades. Specific models with the L84 5.3 V-8 engine have been improved. These changes aim to fix past reliability issues.

GM remains committed to resolving long-standing engine component challenges through continuous technological innovation.

Real-World Case Study: 2010-2016 Model Years

The 2010-2016 GM 5.3 engine lifter problems caused big issues for car owners. Chevrolet trucks and SUVs had major mechanical problems during this time. This showed big concerns with the engine’s lifter design.

Two key case studies show how bad the GM 5.3 Engine Lifter Problems were:

- 2010 Chevrolet Avalanche: Complete engine failure at 70,000 miles

- 2016 Chevrolet Silverado 1500: Substantial lifter malfunction at 121,000 miles

Looking closely at these cases, we see lifter wear and early engine damage. The main problems came from metal issues and design flaws in the GM 5.3 engine.

| Vehicle Model | Mileage | Primary Issue | Repair Cost |

|---|---|---|---|

| 2010 Avalanche | 70,000 | Complete Engine Failure | $5,500 – $8,000 |

| 2016 Silverado | 121,000 | Lifter System Malfunction | $3,200 – $6,500 |

These problems were not just one-offs. They were a big challenge for GM’s manufacturing during these years.

“These ongoing engine troubles highlight the need for regular maintenance and knowing about possible mechanical problems,” said car engineering experts.

Prevention Strategies and Maintenance Protocols

Keeping your GM 5.3 engine in top shape is key to avoiding lifter issues. Owners can lower the risk of lifter failures by following a regular maintenance plan. They should also watch for early signs of trouble.

Recommended Service Intervals

Regular maintenance is vital for your GM 5.3 engine. Here’s a suggested maintenance schedule to help avoid lifter problems:

- Oil changes every 3,000-5,000 miles

- Regular engine inspections every 15,000 miles

- Use high-quality synthetic oil meeting GM specifications

- Replace oil filters at each oil change

Early Warning Detection Methods

Spotting lifter issues early can save you from costly repairs. Keep an eye out for these warning signs:

- Unusual engine ticking or tapping sounds

- Reduced engine performance

- Inconsistent engine idle

- Increased oil consumption

Oil Consumption Monitoring

It’s important to watch how much oil your engine uses. GM says oil consumption should be under 1 quart per 3,200 kilometers (2,000 miles).

| Mileage Range | Recommended Action |

|---|---|

| 30,000-40,000 miles | Increased oil consumption risk |

| Over 1 qt per 2,000 miles | Immediate professional inspection recommended |

By sticking to these preventive steps, GM 5.3 engine owners can keep their engines running smoothly. This helps avoid lifter problems and keeps your engine in great shape.

Repair Options and Associated Costs

Fixing GM 5.3 engine lifter issues can cost a lot. The price depends on how bad the damage is and the repair method used.

There are two main ways to fix GM 5.3 engine lifter problems:

- Partial Lifter Replacement: Cost ranging from $3,000

- Labor: $1,400

- Parts: $1,400

- Shop Supplies: $30

- Tax: $170

- Complete Lifter and Camshaft Replacement: Cost around $4,800

- Labor: $2,800

- Parts: $1,700

- Shop Supplies: $30

- Tax: $275

When choosing a repair for GM 5.3 engine lifter issues, consider a few things:

- Current vehicle mileage

- Warranty coverage

- Long-term vehicle maintenance history

- Projected repair longevity

Most repair shops give a 12-month or 12,000-mile warranty on lifter work. This gives owners some confidence when fixing these engine problems.

Pro tip: Regular maintenance and catching issues early can help avoid expensive repairs for GM 5.3 engine lifter problems.

Performance Impact on Towing and Heavy-Duty Use

GM 5.3 Engine Lifter Problems can really hurt a vehicle’s towing power and overall performance. Truck owners who use their vehicles for heavy tasks need to watch out for lifter issues. These problems can make the engine less reliable.

Towing well depends a lot on the engine’s health, especially with GM 5.3 Engine Lifter Problems. A 5.3-liter EcoTec3 V8 can tow up to 11,500 lbs. But, lifter troubles can cut down this number a lot.

Trucks with lifter problems face several issues, including:

- Less torque (standard torque is 383 lb.-ft.)

- Less power when speeding up

- More chance of engine misfires

- Worse fuel efficiency

| Performance Metric | Healthy Engine | Compromised Engine |

|---|---|---|

| Towing Capacity | 11,500 lbs | Reduced by 20-40% |

| Fuel Economy | 16-23 mpg | 12-18 mpg |

| Torque Availability | 300+ lb.-ft. @ 2,000-5,600 rpm | Inconsistent performance |

Keeping up with maintenance is key to keeping GM 5.3 engines strong during tough towing jobs.

Long-Term Solutions and Engine Modifications

Fixing GM 5.3 Engine Lifter Problems needs more than just quick fixes. Car owners with ongoing lifter issues have several big options. The best choice is often a full engine makeover or a new engine, which can cost about $5,000.

One good fix is the AFM Delete Kit. It gets rid of the Active Fuel Management system, which often leads to lifter failures. This kit stops debris from clogging solenoids, a common lifter failure point around 60,000 miles. It replaces the original AFM lifters with GM LS7 lifters and adds new alignment trays for better engine performance.

Performance lovers might want to upgrade even more. Installing new valve springs from GM LS2/LS3/LS6 models and a new camshaft can help. These changes fix lifter problems and might make the engine run better and last longer. The rebuild takes about 12 hours and includes many parts for better reliability.

If you’re looking for a full solution, talking to a GM engine expert is a good idea. They can give advice based on your car’s needs and how it runs. Thinking about repair costs, performance gains, and long-term reliability will help you decide the best way to handle your GM 5.3 engine’s lifter issues.

FAQs

What are the most common symptoms of GM 5.3 engine lifter problems?

Symptoms include engine ticking or tapping noises and reduced performance. The check engine light may turn on. You might also notice misfires and a loss of power when accelerating.

Rough idling and lower fuel efficiency are other signs. These issues can affect your driving experience.

At what mileage do GM 5.3 engine lifter problems typically occur?

Problems can start between 70,000 and 121,000 miles. However, some vehicles may face issues earlier or later. The 2010-2016 models are more prone to these issues.

How expensive are GM 5.3 engine lifter repairs?

Costs range from 0 for a basic replacement to ,000-,000 for full engine repairs. A complete engine swap can be even pricier. Early detection is key to saving money.

Can I continue driving with suspected lifter problems?

It’s best not to drive with lifter issues. Driving long-term can damage other engine parts. This could lead to more costly repairs.

Are 2023 GM models still experiencing lifter problems?

GM has made improvements in recent models to reduce lifter issues. While not gone, the problems are less common and less severe in newer vehicles.

What preventive maintenance can help avoid lifter issues?

Regular oil changes with high-quality oil are crucial. Keep oil levels right and follow service schedules. Use GM-recommended oil viscosity. Regular engine checks can also help catch problems early.

Do lifter problems affect my vehicle’s towing capacity?

Yes, lifter issues can harm towing performance. Damaged lifters can reduce engine power. This might limit your ability to tow safely and efficiently.

What engine models are most affected by lifter problems?

The GM 5.3L V8 engines in trucks and SUVs from 2010-2016 are most affected. This includes the Chevrolet Silverado, Tahoe, Suburban, and GMC Sierra.

Can aftermarket parts help resolve lifter issues?

Some aftermarket parts are available, but it’s wise to talk to a certified GM technician. Aftermarket parts might void warranties and not solve the problem long-term.

How long does a typical lifter replacement take?

Replacing lifters takes 8-12 hours of labor, depending on the vehicle and damage. The time can vary with the mechanic’s skill and the engine’s complexity.